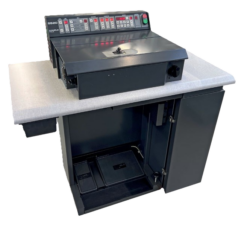

Comelz skiving SS20 computerized machine

The Comelz skiving SS20

- SECTORS: Leather goods, Footwear

- CONFIGURATIONS: Skiving leather.

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

The Comelz skiving SS20 was born from the accurate application of modern mechanical and electronic technology. It represents a major departure from the traditional skiving machine. The machine, in fact, is constantly monitored, it adjusts itself automatically and stays perfectly efficient while in operation.

All developed by Comelz Italy first time functions are performed by mechanical units driven by independent motors operating under the direct control of the computer. The console can be easily reached and the data displays are very clear. An efficient dust collector is built in the frame of the machine.

DATA STORAGE

The Comelz skiving SS20 has a memory for 800 different types of scarf (100 groups of 8) and each one is immediately accessible. It is sufficient to press a button to recall the required type of scarf. The operator can improve or modify the current scarf parameters configuration at nay time. The new adjustment is stored in memory, replacing the former data.

PROCESSING OF WORKPIECES WITH DIFFERENT TYPES OF SCARF

For those workpieces which profile requires different skiving styles it is possible to program the necessary sequence. The operator has only recall on the sequence display the required types of scarf in the correct order. Afterwards, just a slight pressure on the pedal will make the Comelz skiving SS20 shift from one configuration to the next. It is also possible to store these sequences in memory, making use of the ample and versatile memory of the machine.

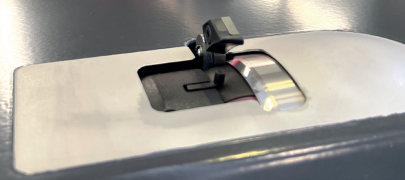

WORKPIECE FEEDING

The feed roller turns, by choice of the operators,

- Continuously, at the predetermined speed

- At a variable speed, controlled by a pedal.

In both cases the work feeding speed can be very accurately set and ut is not influenced by thickness an toughness of the material being processed.

These features make the skiving of workpieces with a complicated outline very easy. A Knee operated switch lifts the presser foot to release the workpiece at any moment

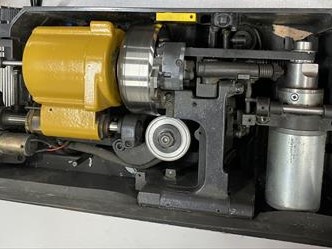

KNIFE SHARPENING AND CRINDSTONE DRESSING

These two operations, which in traditional machines cause a remarkable loss of time, are automatically performed by the Comelz skiving SS20, according to the parameters chosen by the operator (pressure, duration and interval). It is also possible to have the machine performing continuous sharpening for special skiving works. The operator can activate and deactivate knife sharpening and grindstone dressing at any time, within his or her own discretion.

SKIVING

Skiving parameters:

- thickness

- width

- angle

- feed speed

are shown on a display and can be micro metrically adjusted. - movable

- fixed.

Both are present at the same time and can also be alternatively used on the same workpiece. The movable guide allows a fine adjustment of the scarf width. It is possible to program its disappearance under the work area to allow the use of the fixed guide.

This guide, positioned under the presser foot near to knife, is perfect for complicated skiving and for workpieces with very tight curves.

The unavoidable presser foot wear can be compensated directly through the control board of the machine for every scarf at the same time, to guarantee constant skiving quality

Technical data

| Descriptions | Data |

|---|---|

| Scarf width | from 0 to 20 mm |

| Feed rata | from 0 to 700 mm/sec |

| Knife rotation speed | 2700 rpm |

| Electrical requirements | 3-phase (1-phase upon request) |

| Max power consumption | 1200W |

| Net weight | 145 Kg |

| With case | 200 Kg |

| Dimension (mm) | 1.030 x 1.050 x 550 |

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)