Auto nesting and Cutting technology

In the competitive world of leather goods manufacturing, maximizing material utilization and improving production efficiency are vital. Leather auto-nesting technology has revolutionized the industry by automating the layout process for cutting leather pieces, ensuring minimal waste and optimal use of each hide. This technology is essential for manufacturers of shoes, handbags, furniture, and automotive interiors, offering significant savings in both time and materials.

Material Optimization

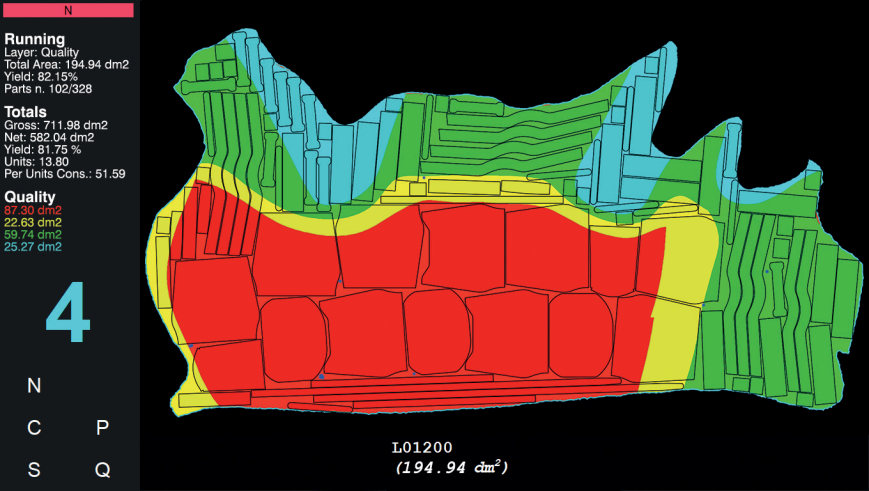

- How it Works: Modern Auto-nesting algorithms such as Ant Colony Optimization (AC), Tabu Search (TS), Constraint Programming (CP),… or self-developed nesting algorithm from Comelz NEK (or NEK Plus) can analyze each hide, accounting for defects, stretch zones, and grain direction to optimize material usage.

- Benefit: Reduces leather waste by up to 15%, making each hide go further by auto nesting

- Example: A shoe manufacturer can sees a 12% reduction in material costs by switching to auto-nesting, utilizing more of each leather hide depend on the models and leather types which are digitized accurately by Comelz NEK or Comelz NEK Plus machine.

Time Efficiency

- How it Works: Traditional manual nesting can take hours to arrange patterns on a hide. Auto-nesting software completes this task in minutes, thanks to advanced algorithms.

- Benefit: Speeds up production cycles and reduces labor costs.

- Example: A factory producing leather handbags cuts preparation time from 2 hours to just 10 minutes per hide through the combination of Comelz NEK for leather digitalizing and Comelz CZ Serie or CZ Plus Serie for leather cutting.

Consistency & Quality

- How it Works: The system identifies quality zones and orients patterns to ensure that pieces are cut from the best parts of the hide.

- Benefit: Results in consistent product quality and higher yields because auto nesting will work in uniform way

- Example: A luxury goods manufacturer achieves uniformity in watch straps, improving customer satisfaction and reducing defects.

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)