Comelz CZ Serie: The most complete solution to meet the wide variety needs of cut

- SECTORS: Leather goods, Footwear, Automotive, Apparel and Furniture

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

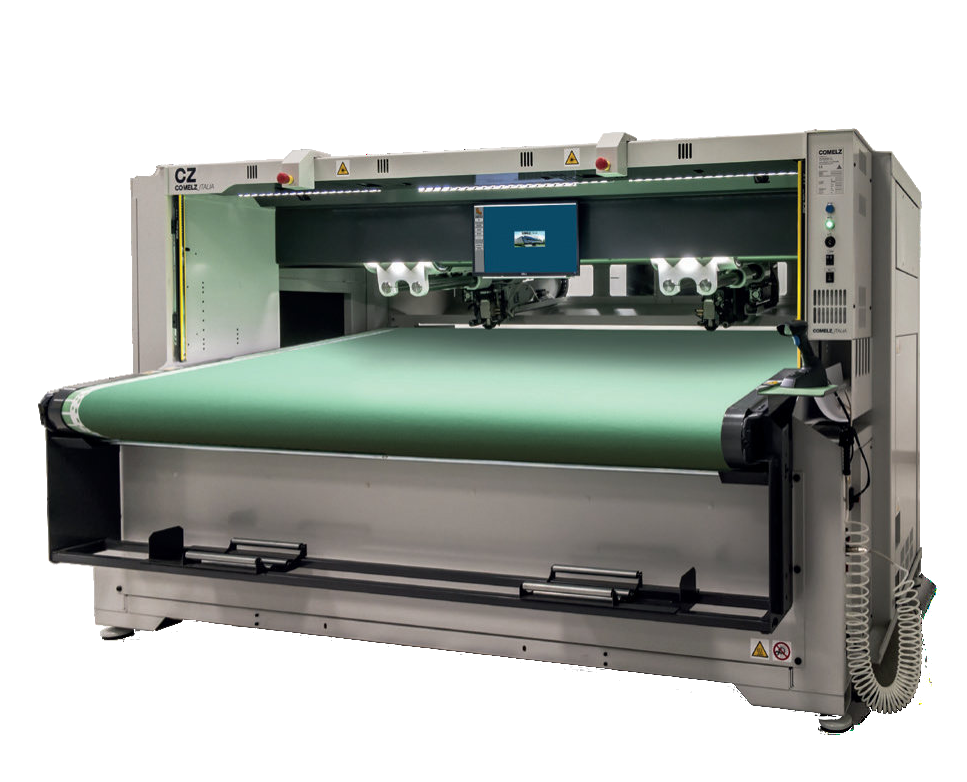

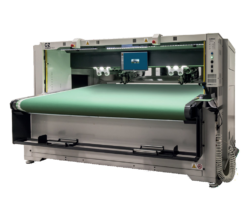

The Comelz CZM CZL CZXL represents the evolution of the winning original concept.

- high production cutting island

- completely ergonomic with tilted work area

The TUV certification obtained for Comelz CZM, CZL, CZXL is a further guarantee of the highest safety standards.

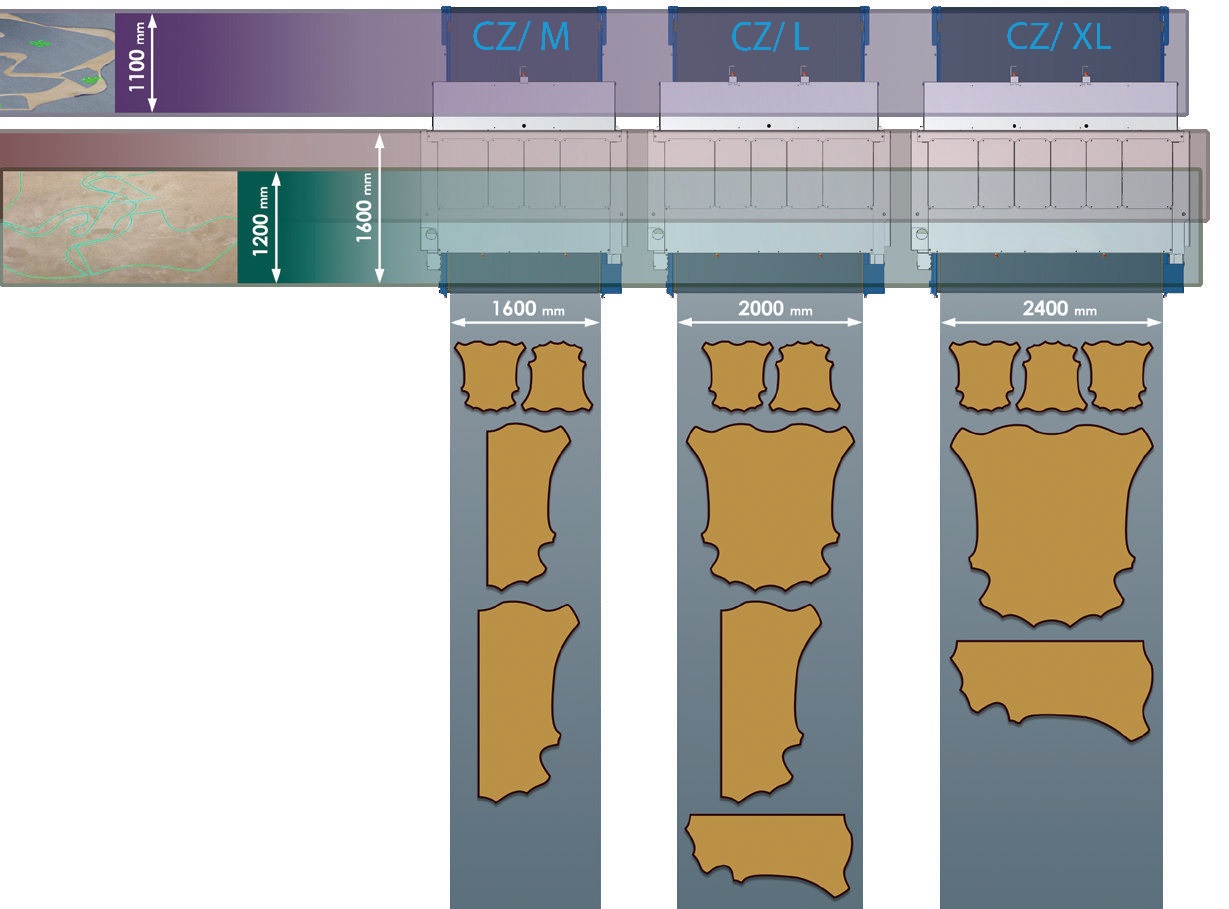

FLEXIBILITY WITH SIZES

A deeper tilted work area allows for handling the hides in large portions, or even entire hides if the area is wide enough. This is the reason why, depending on the hides, everybody can choose the correct width of the conveyor belt among sizes M, L and XL, respectively 1.6, 2.0, 2.4 meter.

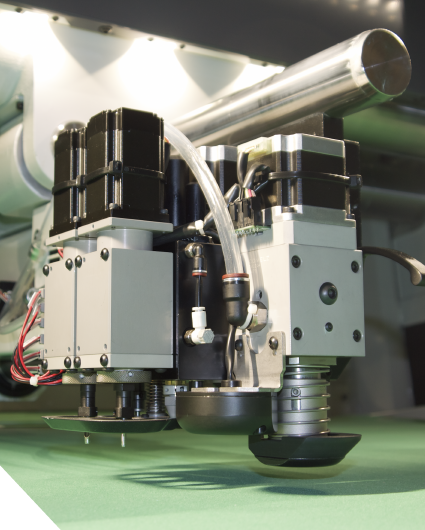

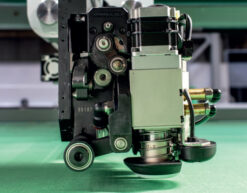

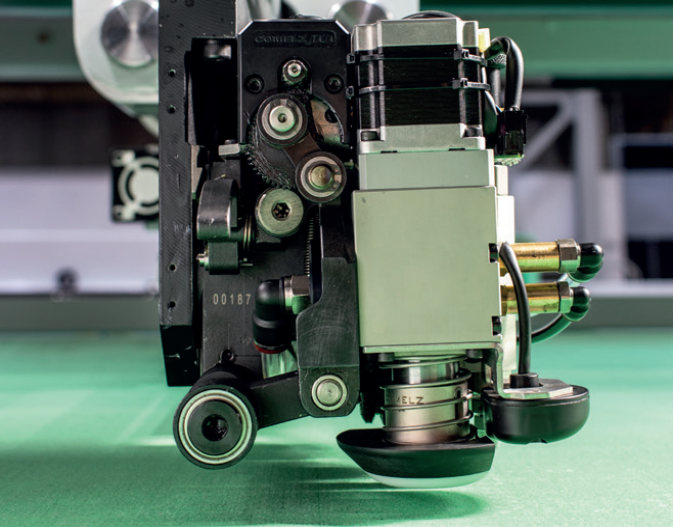

Compact multi-tools heads

Entirely developed, produced and integrated by Comelz, the tools are fast, robust, and reliable. In addition the tools are lightweight and compact improving the mechanical rigidity and allowing for quick and easy access to tool changing due to head rotation.

CUP HEAD SERIES

Evolution of the CU series with pneumatic oscillator available in 3 oscillation strokes of 2, 4 or 8 mm suitable for cutting materials

up to 4.5 mm.

The punching is managed by a maximum of 5 rotating punches mounted on revolver units and the equipment is completed by a pen to mark with interchangeable refill

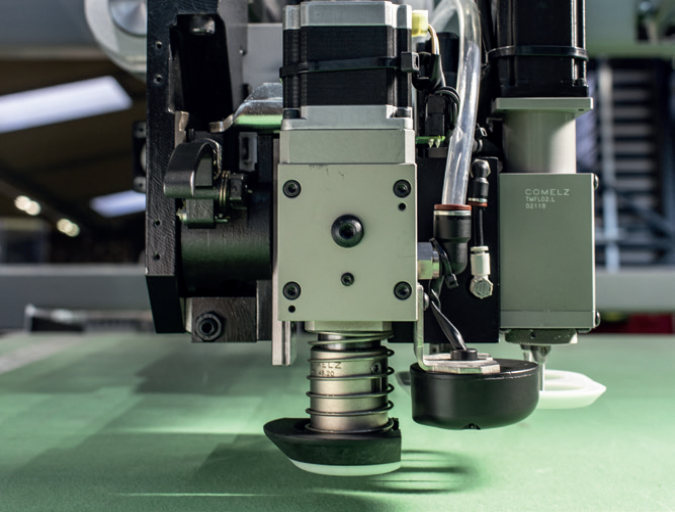

TM HEAD SERIES

Head with pneumatic oscillator available in 3 oscillation strokes of 2, 4 or 8 mm suitable for cutting materials up to 18 mm even

in multi-layered configuration.

2 rotating punches and 2 fixed punches as well as a plate which can be activated by software in cases where it is necessary to improve the retention of the materials during the punching step.

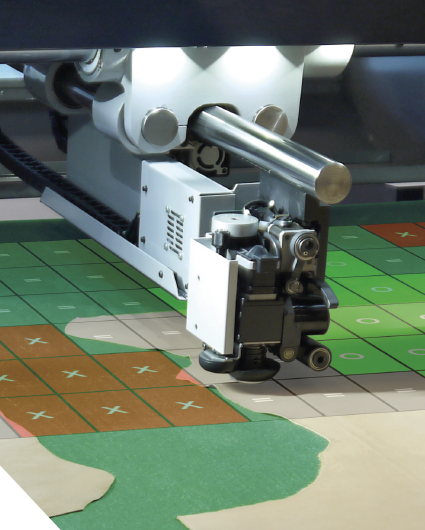

STOP&GO FOR CUTTING CORNERS

The Stop&Go patented system, available in the pneumatic Comelz oscillators, speeds up the execution of fragmented corners because it allows the blade to place in vertical controlled position during every oscillation, in order to get in and out the

material during the cutting of corners without moving the head vertically, which is slower

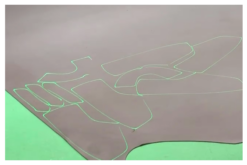

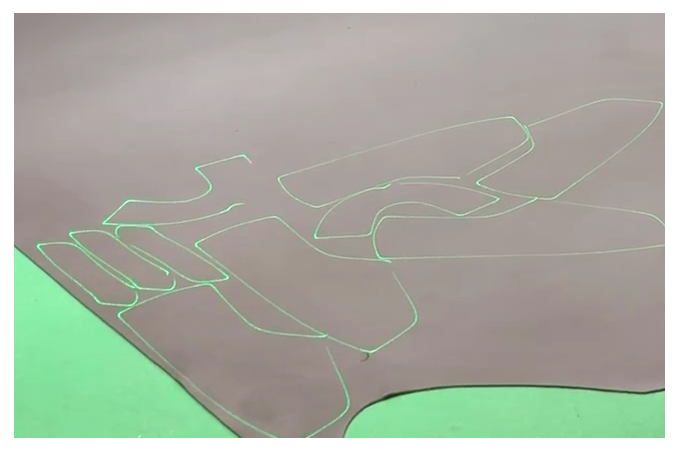

LASER PROJECTORS AND ANTI-REFLECTION LIGHTS

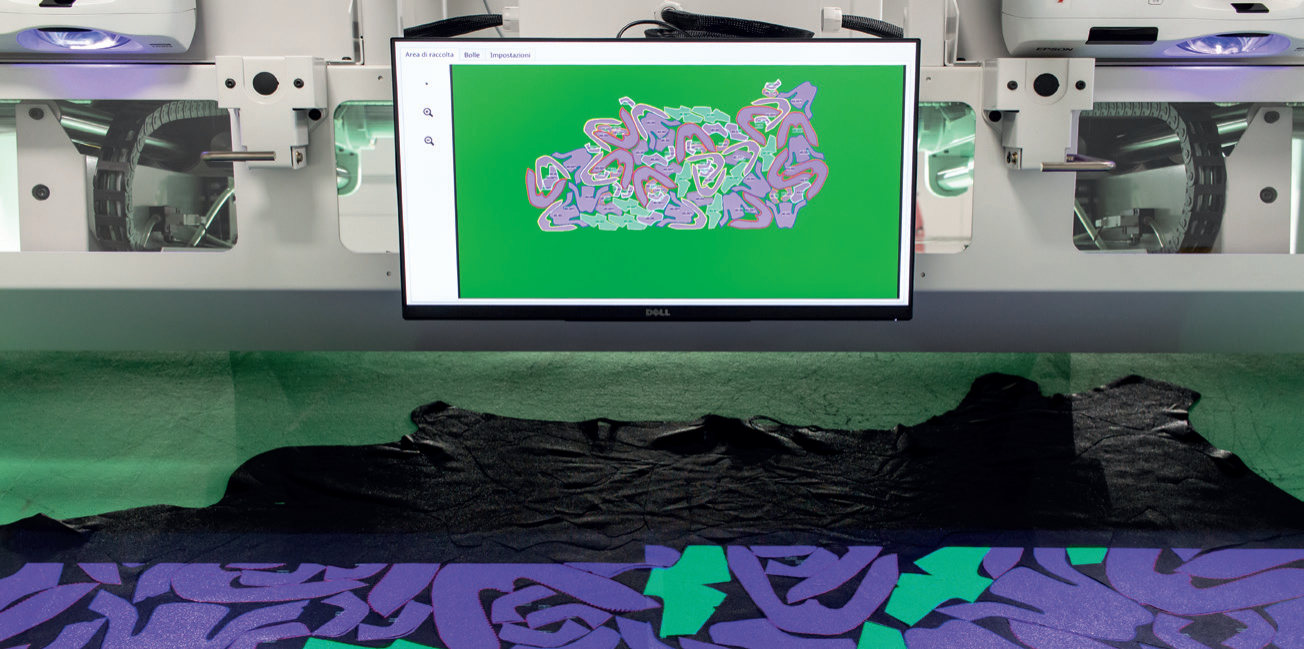

The integrated laser projectors always guarantee complete and optimum visibility of the piece shapes to be nested for every type and colour of material. The large work area is illuminated by a system of LED lamps.

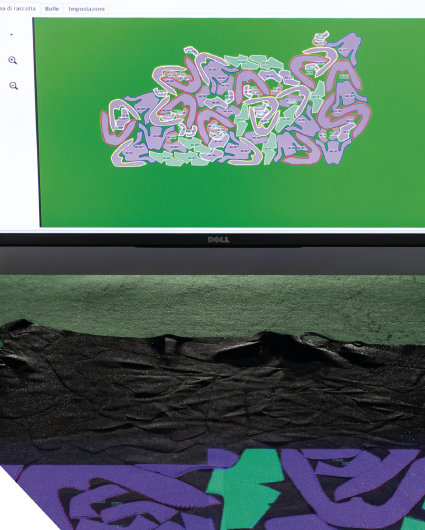

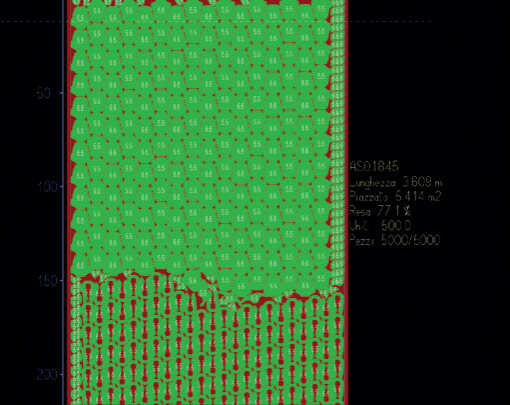

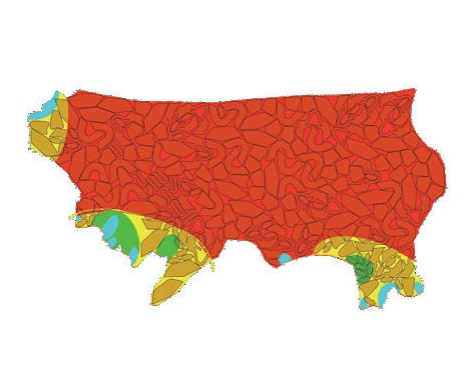

POWER FULL AUTONESTING ENGINE

Algorithm resulting from years of experience in automatic cutting optimization of both synthetic and natural materials. Fully configurable, it offers parameters such as cutting direction, quality areas, pairs and much more, to be taken into account for a constant yield over time. The data are used in the cutting phase to optimize consumption

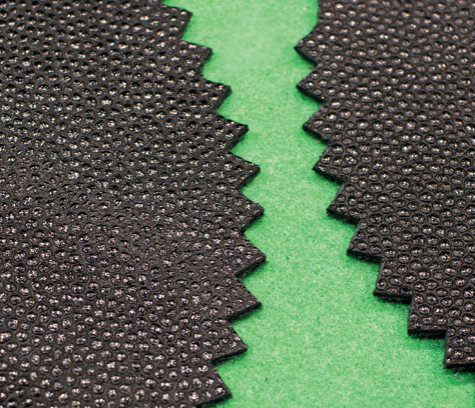

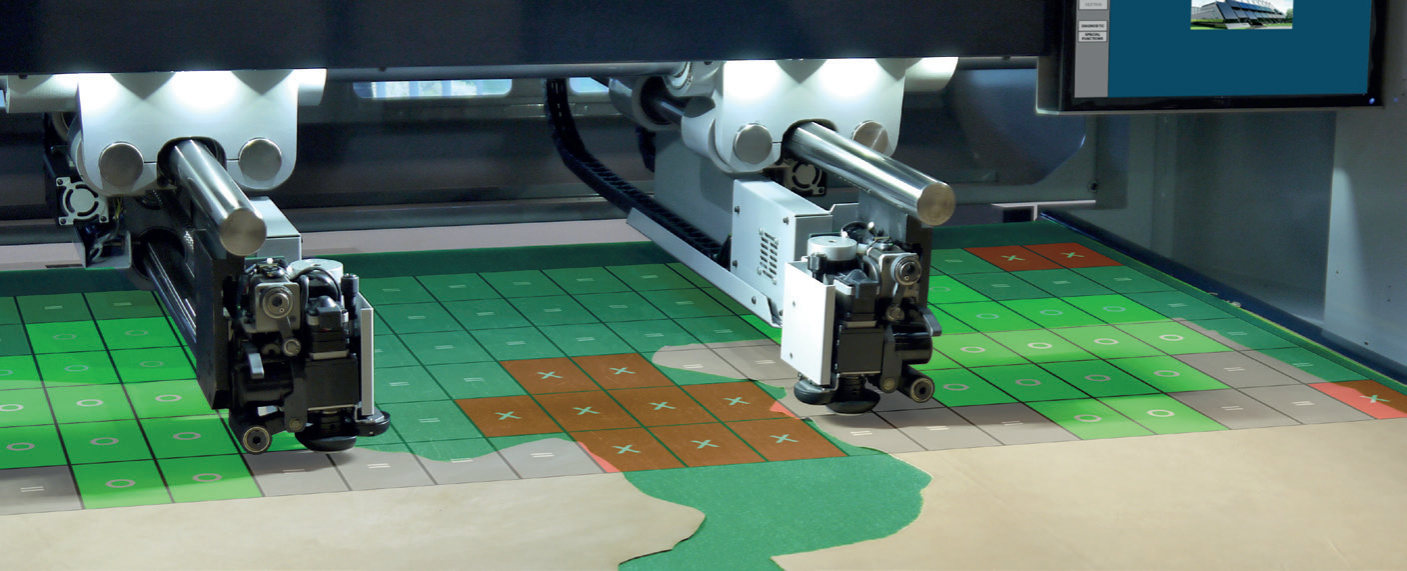

MICRO-SECTOR VACUUM SYSTEM

A sophisticated vacuum system controls a large number of independent micro-sectors, each of just 10 x 14 cm. This concentrate with great resolution the vacuum power only where necessary, considerably reducing vacuum leaks along the irregular outline of the leather.

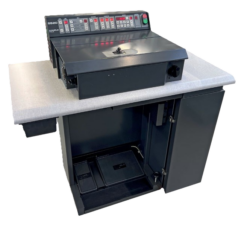

ASSISTED PICK (Optional)

With a touch screen and a dedicated software you can easily identify parts with different size of parts of different articles, send back into the bill of order parts that were potentially damaged, but also control the cutting machine parameters (knife hight, speed, etc.) directly from the collection position. With the aid of high quality LCD projectors, the collection assistance system can be integrated. By projecting different colors on different pieces of measurement, or pieces of different items in the same area to optimize the yield of the material, it is easier to identify and speed up the collection

Technical data

| Descriptions | CZM | CZL | CZXL |

|---|---|---|---|

| Cutting area (mm) | 1500 x 850 | 1900 x 850 | 2300 x 850 |

| Cutting speed | 40 m/min | 40 m/min | 40 m/min |

| Maximum punching frequency (for each head) | CUP head – 300p/min TM head – 600 p/min |

CUP head – 300p/min TM head – 600 p/min |

CUP head – 300p/min TM head – 600 p/min |

| Air supply | 300 L/min a 6 bar | 300 L/min a 6 bar | 300 L/min a 6 bar |

| Power supply | 3 phase 400V-50/60 Hz 3 phase 220V-50/60 Hz (optional) |

3 phase 400V-50/60 Hz 3 phase 220V-50/60 Hz (optional) |

3 phase 400V-50/60 Hz 3 phase 220V-50/60 Hz (optional) |

| Maximum power consumption | 16 KVA/24KVA | 16 KVA/24KVA | 16 KVA/24KVA |

| Net weight (Kg) | 2.462 | 2.731 | 2.935 |

| Gross weight (Kg) | 2.742 | 2.991 | 3.195 |

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)