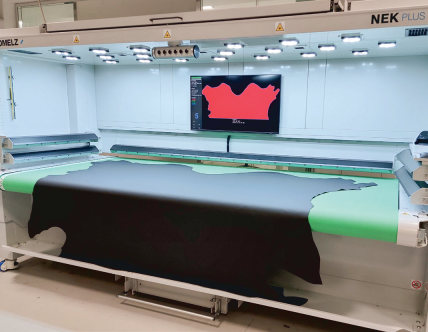

Comelz NEK Plus the next generation tool for digitizing leathers

Comelz NEK Plus the next generation tool for digitizing leathers

- SECTORS: Leather goods, Footwear, Automotive, Furniture

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

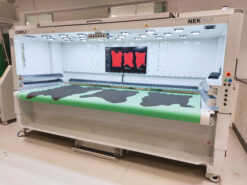

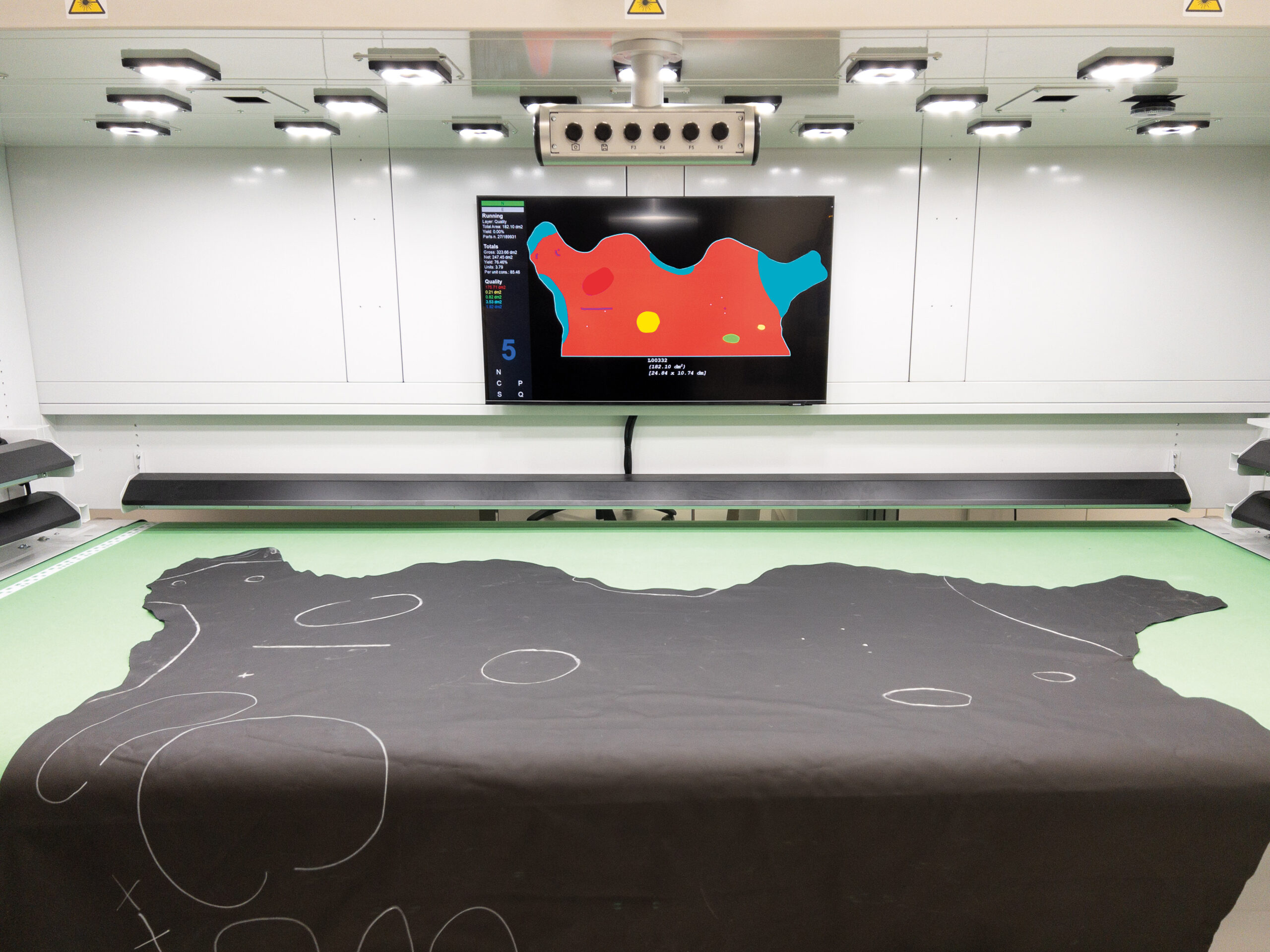

Digitalizing skins together with powerful next generation Comelz Nesting engine.

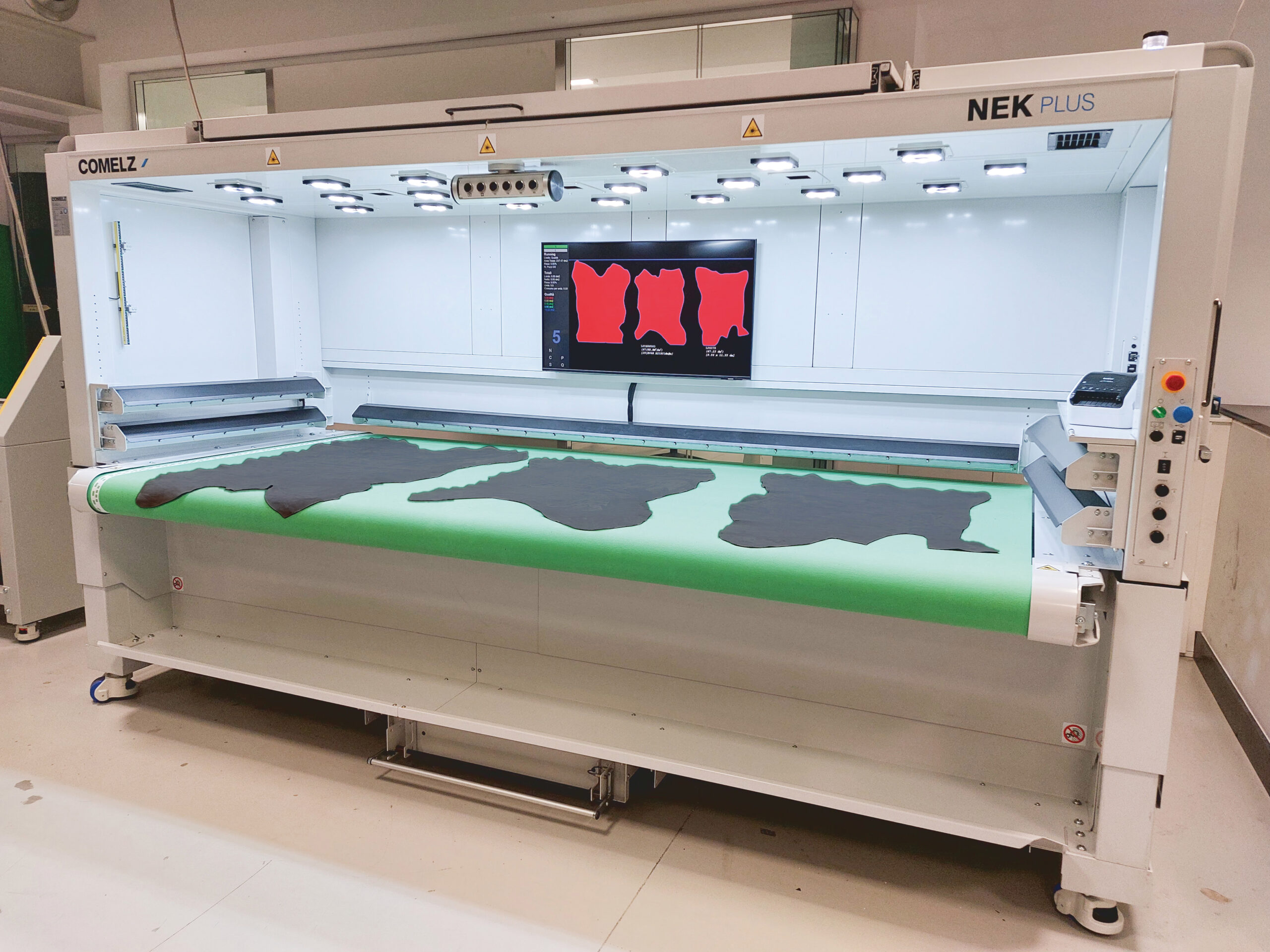

High tech vision system with Comelz’s cameras

Comelz NEK Plus with a unique vision system of 8 industrial cameras allows for an instant and accurate detection of the hide and of the marking pen. The high number of cameras, thanks to small vision angles, improves the accuracy when detecting hides not perfectly flat. Thanks to the short distance from the work area there is no need to recalibrate the machine frequently.

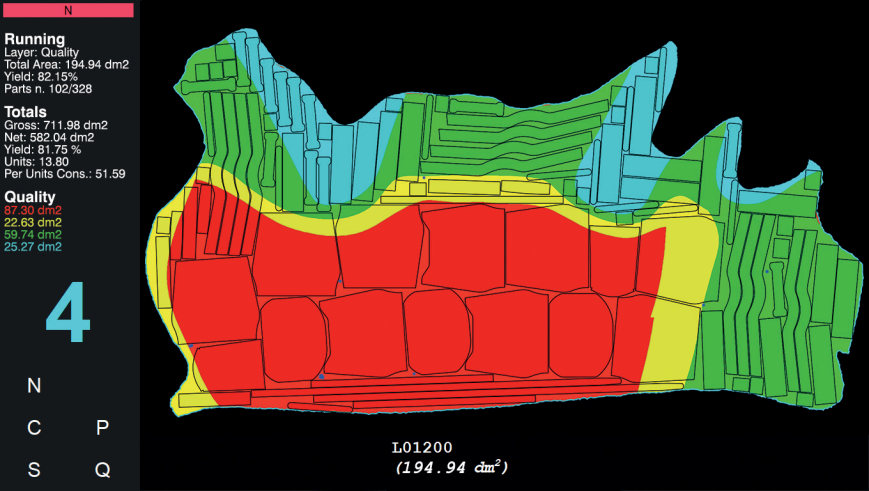

Digitalization and nesting with Comelz NEK Plus

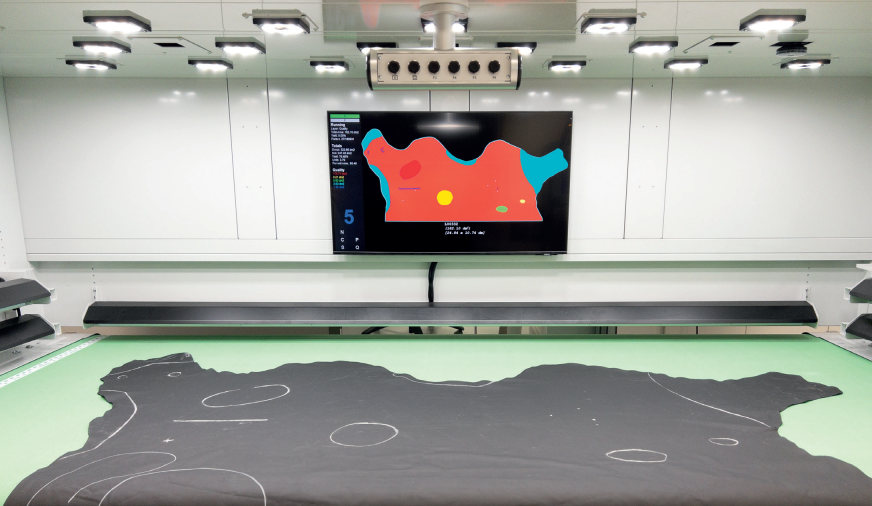

Leather Measurement/Grading and Yield Calculation (based on real cutting simulation of single or multiple hides).

Leather Digitalizing (marking of defects and quality areas) and Comelz Nesting engine for pattern nesting (manual nesting, manual nesting of the main pieces and automatic nesting for all other pieces, automatic nesting).

Only Leather Digitalizing (a real time automatic nesting is done directly on the machine, while cutting).

Comelz NEK Plus with Enhanced Light System

Comelz NEK Plus with this unique, innovative patent pending system form Comelz, it is possible to illuminate every area of the hide from multiple directions allowing to detect defects that before was possible only when the

hides were placed under stretch conditions and in a highly tilted position that is non-ergonomic for

the operator.

- A total of 600 individual power LEDs.

- 336 LED are used for diffused light.

- 264 LED are equipped with special focus lenses for directional light.

- 64 individually controlled dimmers.

- Adjustable hue (from 2700K warm white to 6500K cold white) for diffused light.

- Antiglare system for an ergonomic work environment even after extended periods of time.

- Different configurations available for different types or colors of hides.

- All configurations can be stored and recalled.

Laser projectors of Comelz NEK Plus

Three last generation laser projectors are used to display on the hide the defects marked by the operator. We use laser projector since they are the only way to display something on a highly illuminated work area. Laser projectors are also more accurate than regular projectors.

Chalk recognition (Optional)

An optional software on Comelz NEK Plus can automatically detect defects of hides pre-marked with chalks or crayons.

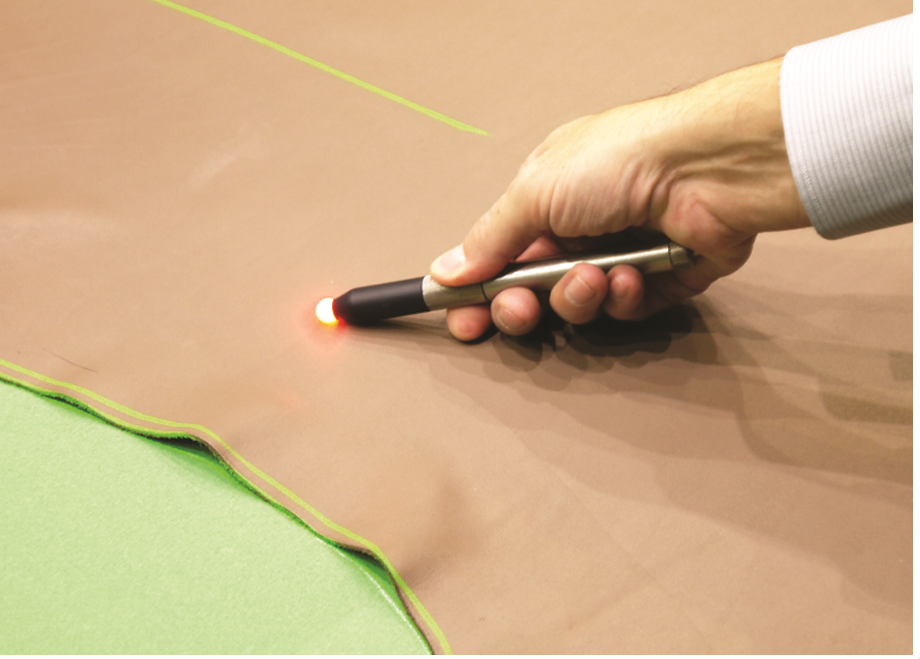

Virtual pen

Virtual pen that used to mark the hide defects/quality areas and for the control of the main system commands. Programmable bidirectional bar for handling or operational functions.

Combination working together with cutting Comelz cutting machines

- The digitalized leathers can transfer to cutting machines to next the processes of nesting and cutting.

- Can be combined with both CZ series (M/L/XL) and new generation of cutting machines like CZ+/L and CZ+XXL

Technical data

| Descriptions | Data |

|---|---|

| Working area (W x L) mm | 3.000 x 1.400 |

| Vision resolution | 0,5 mm |

| Maximum angle of view | 22° |

| Maximum illuminance | 11.000 lux |

| Power supply (three-phase+N) | 400 V – 50/60 Hz |

| Maximum power consumption | 3 KW |

| Net weight | 1.960 Kg |

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)