Water-Based Adhesive Spray Technology in the Production of Leather Shoe Straps, Watch Straps, and Belts

Introduction to Water-Based Adhesive Spray Technology

Water-based adhesive spray technology is becoming a major trend in the leather goods industry, especially for bonding leather shoe straps, watch straps, and belts. By using water-based adhesives, the manufacturing process is not only eco-friendly but also optimizes adhesion, reduces material waste, and enhances product quality.

The video you provided demonstrates the real-world application of automated adhesive spraying systems, which improve productivity, ensure high precision, and minimize errors in the bonding process for small leather goods such as shoe straps, watch straps, and belts.

1. Key Benefits of Water-Based Adhesive Spray Technology in Leather Goods Production

🔹 Safe and Environmentally Friendly

✅ Solvent-free (VOC-free), reducing air pollution and protecting worker health.

✅ No strong chemical odor, ensuring a clean and safe working environment.

✅ Easy to clean with water, eliminating the need for harsh chemical solvents.

✅ Compliant with environmental standards such as REACH, RoHS, and LEED.

🔹 Cost Savings in Production

✅ Precise adhesive application, reducing material waste.

✅ Faster spraying compared to manual brushing, increasing production efficiency.

✅ Lower labor costs, as automated adhesive spraying minimizes manual work.

✅ No need for expensive ventilation systems, cutting infrastructure costs.

🔹 Improved Durability and Adhesion Quality

✅ Even adhesive distribution, preventing inconsistencies seen in manual application.

✅ Does not harden leather, preserving the softness and flexibility of shoe straps, watch straps, and belts.

✅ No yellowing or discoloration, maintaining the aesthetic appeal of luxury leather goods.

✅ Heat-resistant, ensuring long-lasting durability and preventing peeling over time.

🔹 Versatile Application on Multiple Materials

Water-based adhesives are highly adaptable and can bond a wide range of materials commonly used in footwear, watch straps, and belts, including:

✔ Genuine leather (Full-grain, Top-grain, Nubuck, Suede, Aniline, Pull-up, etc.)

✔ Synthetic leather (PU, PVC, microfiber)

✔ Textiles, nylon, polyester, sports mesh

✔ Rubber, EVA, TPU, and recycled materials

The adhesive spraying system allows adjustable pressure and flow rates, ensuring optimal adhesion for different materials.

2. Practical Applications of Water-Based Adhesive Spray Technology

📌 Adhesive Spraying for Leather Shoe Straps

✔ Bonds leather straps to the insole or inner lining without affecting flexibility.

✔ Creates a strong bond between multiple material layers while maintaining aesthetics.

✔ Prevents thick adhesive buildup, keeping straps soft and comfortable.

📌 Real-world example: Leading brands like Nike, Adidas, and Louis Vuitton have transitioned to water-based adhesives to enhance sustainability and reduce environmental impact.

📌 Adhesive Spraying for Watch Straps

✔ Bonds the outer leather layer with the inner lining, ensuring durability and preventing peeling.

✔ Secures leather edges without distorting the material.

✔ Enhances the longevity of watch straps, ensuring they withstand tension and stretching.

📌 Real-world example: Luxury watch brands such as Rolex, Omega, and Tag Heuer use advanced adhesive technology to ensure their leather watch straps remain intact over time.

📌 Adhesive Spraying for Leather Belts

✔ Bonds outer leather to the inner core securely.

✔ Prevents excessive adhesive buildup, keeping belts soft and flexible.

✔ Enhances tensile strength and long-term durability, reducing the risk of adhesive failure.

📌 Real-world example: Fashion houses like Gucci, Hermès, and Montblanc demand high-quality adhesives to ensure their belts last for years.

3. Real-World Implementation of Water-Based Adhesive Spraying Systems

The video showcases automated water-based adhesive spraying systems used in various production stages, including:

📌 Stage 1: The machine evenly sprays a thin adhesive layer onto shoe straps, watch straps, or belts.

📌 Stage 2: Components are pressed together for strong bonding.

📌 Stage 3: Once dry, the product is inspected to ensure no excess adhesive and a uniform bond.

💡 Key takeaways from the video:

- Fast spraying process – covers a surface in just seconds.

- Adjustable adhesive application – tailored to different materials and product designs.

- Minimal manual labor required, reducing production costs and increasing output.

4. Industry Trends and Future of Water-Based Adhesive Spray Technology

🔥 Upcoming developments:

- AI and automation integration to optimize adhesive application for each product type.

- Enhanced compatibility with sustainable materials, such as bio-based leather and recycled components.

- Improved water-based adhesive formulations to increase bond strength and flexibility.

- Wider adoption in the luxury fashion industry, enabling brands to meet sustainability goals.

📌 Prediction: In the coming years, water-based adhesive spray technology will become the industry standard for manufacturing footwear, watch straps, and belts, fully replacing traditional solvent-based adhesives.

5. Conclusion

👉 Water-based adhesive spray technology offers exceptional advantages in producing leather shoe straps, watch straps, and belts:

✔ Health and environmental safety – Solvent-free, VOC-free, non-toxic

✔ Cost savings – Reduced adhesive waste, higher productivity

✔ Superior quality – Maintains leather softness, ensures long-lasting bonds

✔ Versatile applications – Compatible with various natural and synthetic leather materials

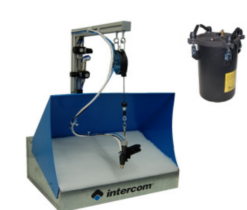

Intercom I388V4 spraying WBA Ecostick for leather of watch straps

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)