WATER-BASED ADHESIVE SPRAY TECHNOLOGY – OPTIMIZING THE HANDBAG MANUFACTURING INDUSTRY

Water-based adhesive spray technology is increasingly being adopted in the handbag manufacturing industry, offering multiple benefits in terms of product quality, production efficiency, and environmental sustainability.

1. Benefits of Water-Based Adhesive Spray Technology in Handbag Production

🔹 Safe and Environmentally Friendly

✅ Water-based adhesives contain no volatile organic compounds (VOCs), significantly reducing air pollution and fire hazards in factories.

✅ Meets the highest environmental standards, ensuring worker safety and compliance with sustainability regulations.

✅ Odor-free, improving working conditions in production facilities.

🌱 Water-based adhesives align with global environmental initiatives and comply with international standards such as REACH, RoHS, and LEED.

🔹 Cost and Material Savings

✅ Precise adhesive application, minimizing waste and optimizing production costs.

✅ Automated spray systems enhance production efficiency, reducing human error and material overuse.

✅ Reduces maintenance costs, extending the lifespan of production equipment.

📌 Case Study: Intercom’s automated adhesive spray systems have helped businesses reduce adhesive consumption by 30 – 40% compared to manual rolling methods.

🔹 Improved Product Quality

✅ Strong adhesion, ensuring secure bonding on leather, synthetic leather, and fabric materials.

✅ No yellowing or material discoloration, making it ideal for light-colored and white handbags.

✅ Resistant to high temperatures, providing long-lasting durability.

💡 Key Advantage: Water-based adhesives do not seep into leather or fabric, preserving the original softness and aesthetics of handbags.

🔹 Versatile Application

✅ Compatible with multiple materials, including leather, faux leather, glossy leather, cotton backing, HD, Kimlon, nylon, PVC, PU, fabric, and woven mesh.

✅ Adjustable spray settings to accommodate diverse production requirements.

✅ Can be used for various handbag styles, from luxury handbags to casual tote bags and backpacks.

📌 Case Study: Leading fashion brands are adopting water-based adhesive spray technology to meet sustainability targets and improve production efficiency.

2. Real-World Applications of Water-Based Adhesive Spray Technology

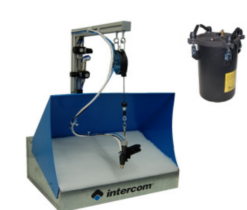

🔹 Automated Adhesive Spray Systems

Many handbag manufacturers have invested in automated adhesive spray technology to improve productivity and product quality.

📌 Advantages of Automated Adhesive Spray Systems:

✅ Increase production efficiency by 25 – 30% compared to manual application.

✅ High precision, eliminating adhesive inconsistencies.

✅ Time-saving, optimizing the production process.

🔹 Applications in Handbag Manufacturing

Water-based adhesive spray technology is used for:

✔ Bonding layers of leather and synthetic materials.

✔ Attaching fabric linings and structural components.

✔ Gluing reinforcement parts inside handbags for added durability.

💡 Key Feature: Water-based adhesives help maintain the softness of materials, preventing the stiffness often caused by solvent-based adhesives.

3. Market Trends and Future Potential of Water-Based Adhesive Spray Technology

🌍 The Future of Sustainable Manufacturing in Handbags

With a global shift towards eco-friendly production, top handbag brands are transitioning to water-based adhesives to:

✔ Reduce environmental impact and align with sustainability goals.

✔ Comply with stricter labor and safety regulations.

✔ Enhance brand value through environmentally conscious products.

📌 Case Studies:

- Luxury handbag brands are integrating water-based adhesive technologies to enhance sustainability.

- Mass-market manufacturers are adopting automated spray systems to improve efficiency and quality.

4. Conclusion – Is Water-Based Adhesive Spray Technology the Best Choice?

👉 If you are looking for a high-performance, cost-effective, and eco-friendly adhesive solution, water-based adhesive spray technology is the ultimate choice.

👉 This method not only enhances product quality and reduces production costs but also meets global sustainability standards.

Recommend

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)