ANALYSIS OF WATER-BASED ADHESIVE SPRAY TECHNOLOGY IN SHOE UPPER PRODUCTION

Introduction to Water-Based Adhesive Spray Technology in Shoe Upper Manufacturing

The shoe upper is a crucial part of footwear, made from various materials such as leather, fabric, mesh, PU, PVC, or synthetic fibers. Manufacturing shoe uppers requires strong adhesion between multiple material layers while maintaining aesthetic appeal, flexibility, and durability.

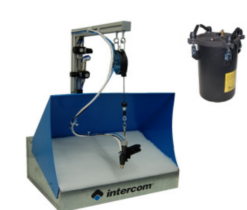

Water-based adhesive spray technology has become a safe, efficient, and environmentally friendly solution to replace traditional manual adhesive application. The videos you provided showcase how automated adhesive spraying systems optimize shoe upper production by reducing material waste, improving efficiency, and enhancing product quality.

1. Benefits of Water-Based Adhesive Spray Technology in Shoe Upper Production

🔹 Safe and Environmentally Friendly

✅ VOC-free, reducing environmental pollution and improving worker safety.

✅ Odorless, ensuring a cleaner and more comfortable workspace.

✅ Easy to clean with water, eliminating the need for hazardous chemical solvents.

✅ Reduces fire hazards in factories, ensuring safer manufacturing conditions.

📌 Real-world example: Leading footwear brands like Nike, Adidas, and Puma have adopted water-based adhesives to minimize environmental impact and meet sustainable production standards.

🔹 Cost Savings and Production Optimization

✅ Fast and precise adhesive spraying, reducing adhesive consumption compared to manual application.

✅ Accelerates bonding processes, shortening production time.

✅ Minimizes human error, thanks to automated adhesive spraying systems.

✅ No need for high-capacity ventilation systems, reducing factory operational costs.

📌 As seen in the videos, automated adhesive spraying ensures uniform application on shoe uppers, improving adhesion strength and reducing material waste.

🔹 Enhanced Durability and Adhesion Quality

✅ Even adhesive distribution, ensuring strong bonding between material layers.

✅ Does not harden leather or fabric, maintaining the shoe’s flexibility and comfort.

✅ Prevents yellowing or material discoloration, crucial for premium shoe production.

✅ Heat and moisture-resistant, ensuring long-lasting adhesive strength.

📌 Real-world example: High-performance sports shoes rely on water-based adhesive technology to maintain flexible yet durable shoe uppers.

🔹 Compatibility with Various Shoe Upper Materials

Water-based adhesive spray technology is compatible with various materials, including:

✔ Genuine leather (Full-grain, Top-grain, Nubuck, Suede, Aniline, etc.)

✔ Synthetic leather (PU, PVC, microfiber, synthetic leather)

✔ Textile fabrics, sports mesh, nylon, polyester

✔ Rubber, EVA, TPU, and recycled materials

📌 As seen in the videos, the adhesive spray system can adjust pressure and adhesive flow to ensure optimal bonding for each material type.

2. Real-World Applications of Water-Based Adhesive Spraying in Shoe Upper Production

📌 Adhesive Spraying for Sports Shoe Uppers

✔ Ensures strong bonding between mesh and inner padding layers, enhancing durability.

✔ Maintains material elasticity, providing flexibility for athletic movements.

✔ Prevents adhesive failure under frequent stretching and impact.

📌 Real-world example: Nike Air, Adidas Ultraboost, and Puma RS-X incorporate water-based adhesives to ensure high durability and comfort in their sports shoes.

📌 Adhesive Spraying for Premium Leather Shoe Uppers

✔ Preserves the natural grain and color of leather, avoiding material distortion.

✔ Creates strong bonds between leather and lining layers, ensuring long-term durability.

✔ Keeps leather soft and flexible, providing premium comfort.

📌 Real-world example: Luxury brands like Gucci, Louis Vuitton, and Berluti use water-based adhesive spraying to produce high-end leather shoes that are both durable and elegant.

📌 Adhesive Spraying for Formal and Safety Shoes

✔ Securely bonds the shoe upper to the outsole, enhancing durability for long-term wear.

✔ Resistant to heat and moisture, ideal for harsh working environments.

✔ Meets occupational safety standards, ensuring strong, long-lasting adhesion.

📌 Real-world example: Timberland, Red Wing, and Caterpillar are adopting water-based adhesives in their safety shoe manufacturing to improve product longevity and environmental sustainability.

3. Future Trends and Innovations in Water-Based Adhesive Spray Technology

🔥 Emerging Trends:

- Integration of AI and automation to precisely control adhesive spraying.

- Improved water-based adhesive formulations for stronger and faster-drying bonds.

- Adoption across various footwear categories, from athletic to luxury leather shoes.

- Sustainability-driven innovations, aligning with international environmental standards.

📌 Future Outlook: Water-based adhesive spray technology will become the industry standard in footwear production, ensuring higher quality, increased efficiency, and reduced environmental impact.

4. Conclusion

👉 Water-based adhesive spray technology delivers exceptional advantages in shoe upper manufacturing, including:

✔ Health & Safety – VOC-free and non-toxic

✔ Cost Efficiency – Reduced adhesive waste and optimized production speed

✔ Superior Quality – Maintains material softness and ensures strong adhesion

✔ Versatile Applications – Suitable for a wide range of shoe upper materials

Intercom spraying WBA for blocking pump lady shoes

Recommend

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)