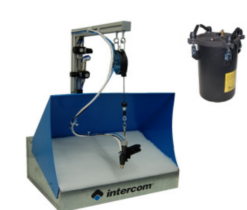

Automation Machine A2.300

Automatic bonding system, equipped with

a 100 cm insulated drying tunnel with hot

air which can reach temperatures up to

110 degrees with circulation of internal air

to minimise the consumption; spray gun

model G9 with jet that can be adjusted

from a cone shape of 15 mm up to 200

mm, adjustable conveyor belt 270 cm with

chain, aspiration equipped with two motors

for optimum performance and Teflon

stainless steel adhesive tank 10 lt. capacity.

On request, it is possible to add a second

spray gun on the axle in order to use

different kind of adhesives and or one or

more manual spray guns.

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

The operator places the materials on the padded carpet of the conveyor belt

which automatically brings the materials under the spray gun where the

adhesive is applied in a uniform way. Afterwards the materials go inside the

drying tunnel for quick drying of the adhesive under any climatic condition. At

the tunnel exit the materials are ready to be coupled. Thanks to this system,

the materials are not displaced so there are no idle times due to the manual

management of these working phases. The aspiration system has been

completely redesigned with the installation of two motors that prevent even

the lightest materials from moving due to the air coming out from the spray

gun. Thus, it guarantees the total absence of fine dust particles of adhesive

around the machine. The conveyor belt with chain guarantees an efficient

moving process even when the filter becomes heavier due to the adhesive

being filterd. This perfect temperature control inside the oven results in

reduction of drying times and therefore, we have managed to design a

machine of reduced length resulting in less space occupied by the machine in

the working area.

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)