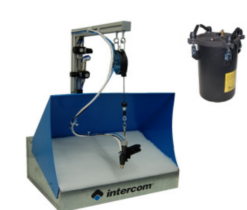

Automation spraying egde machine DV.100

Polifemo – Automatic Gluing Machine with Pallet System: Elevate Your Production Efficiency

Polifemo is an advanced automatic gluing solution equipped with an intelligent pallet system. This cutting-edge machine offers the perfect combination of modern technology and automation, allowing businesses to boost production speed, ensure exceptional adhesive quality, and optimize costs. Here’s why Polifemo is the ultimate choice for your manufacturing line.

Advanced Technology & Automation

Polifemo integrates state-of-the-art technology for high-precision gluing. It is equipped with two G6 automatic spray guns with 1.2 mm nozzles, allowing spray widths from 3 mm to 22 mm with an accuracy of ±1 mmne is controlled by an industrial computer with a 6-megapixel camera, an Ethernet network interface for remote access, and a 19-inch LCD screen for process monitoring . Its 4-control system (X-Y-Z-W) works in tandem with pattern editing software, enabling users to program adhesive paths with high precision and flexibility . All settings are st be recalled effortlessly, ensuring consistent automation and efficiency .

Production Optimization*l pallet system in Polifemo eliminates downtime in the gluing process. While one pallet enters the spraying chamber, the other pallet automatically exits, allowing operators to load new materials simultaneously . This continuous in-and-out mechanism terrupted workflow, eliminating bottlenecks caused by manual handling.

Additionally, the automatic image recognition system enables the machine to precisely identify each component on the pallet and apply adhesive according to pre-programmed specifications without requiring human intervention . As a result, production speed is significantly increating wasted time while maintaining high precision .

Superior Gluing Quality

Polifemo ensures flawless an adhesive application on every product. The two automated spray guns move in a pre-programmed pattern, applying the exact amount of glue at precise locations—whether for narrow edges or large surfaces. The control system allows users to set parameters such as distance from the edge and adhesive thickness based on material type, ensuring a strong yet waste-free bond.

A high-power vacuum suction system stabilizes materials throughout the spraying process, preventing lightweight components from shifting due to airflow from the spray guns . This vacuum system also eliminates adhesive dust dispersion, keeping clean and safe** . The result? Consistently high-quality bonds, aesthetically perfect adhesive lines, and mini defects—enhancing your brand reputation.

Economic Benefits

In addition to performance and quality, Polifemo offers significant economic advantages:

- Reduced adhesive waste: Precise spraying optimizes glue usage, preventing excessive application and saving costs.

- Lower labor costs: A single operator can efficiently run the system, replacing multiple manual gluing workers.

- Minimized defective products: Consistent adhesive application reduces material wastage and rework.

- Energy efficiency: The machine is optimized to consume only ~1.5 kWh on average , lowering electricity expenses.

These combined factors make Polifemo a high-return investment, ensuriI (Return on Investment)** while increasing overall profitability.

Versatile Applications

Polifemo is an adaptable gluing solution suitable for various industries. It can handle a wide range of materials—including leather, fabric, rubber, wood, and plastic—thanks to customizable adhesive spraying modes for different applications. Key industries benefiting from Polifemo include :

- Leather Goods & Fashion Accessories: Efficiently bonds bags, wallets, belts, and more, enhancing productio in premium leather goods manufacturing.

- Footwear & Apparel: Automated spraying for shoe components (uppers, soles) and some textile applications, ensuring strong bonds without compromising aesthetics.

- Furniture & Interior Design: Used in sofa, seat cushions, and decorative elements, ensuring robust, seamless adhesive application.

- Packaging & Printing: Perfect for carton sealing, luxury packaging, bookbinding, and album production, delivering clean, precise glue lines.

- Automotive Industry: Applies adhesive for car interior components, dashboards, floor mats, and soundproofing materials, ensuring long-lasting, durable bonding.

Thanks to its multi-purpose adaptability, businesses can invest in one machine and use it across multiple production lines, maximizing equipment efficiency.

Conclusion

With its cutting-edge technology, superior performance, and cost-efficiency, the Polifemo Automatic Gluing Machine with Pallet System is the ideal solution to revolutionize your manufacturing process. This system not only optimizes production, guarantees high-quality output, but also ensures substantial cost savings. Contact us today to experience state-of-the-art gluing automation—a game-changer for modern industry. 🚀

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

Item description: DV.1

Automatic machine, managing the pieces using pallet, conceived for all kind of perimetric bonding and /or for bonding any point of a piece placed on a flat surface.

Equipped with 2 spray guns model G6 with adhesive nozzle mm 1,2 whose width of jet goes from a minimum of 3 mm up to a maximum of 22 mm with a mistake of +/- 1 mm.

The machine is equipped with industrial Computer, 6 megapixel telecamera, Network Interface Controller preset for remote access and monitor LCD 19″.

The operator places on one pallet the components to be bonded; by putting the pallet with the components to be sprayed inside the machine, the other pallet with sprayed pieces will go out automatically.

The machine is able to recognize the image of each component earlier photographed, the kind of bonding pre-defined by the models editor software and to carry out the requested bonding on each component according to the following parameters: width in mm, distance from the edge and quantity of adhesive according to the absorbing level of the material.

All instructions set by the operator are saved on a file and can be re-called with a simple click during the next working process.

Specific:

| Capacity m3/h: 3050 | Volt: 400 Vac | Prevalence: 53 | Air lt/min: | Bar exercise: 0 |

| Decibel (dB): <80 | Watt: 1500 | Hertz: 50 | Ampere: 7 | Average consumption: 1,5 KW-H |

| Gross Weight kg: 0 | Tare Kg: -648 | Lenght mt: 2,54 | Height mt: 2,52 | Volume m3: 12,48 |

| Net Weight kg: 648 | Width mt: 1,95 | Usable Depth: 54,5 x 72 | ||

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)