Automation spraying full surface machine A2.300

🔥 ADVANCED GLUING TECHNOLOGY – OPTIMIZED PERFORMANCE

✅ Fully Automated Process

- The 210cm chain conveyor automatically transports materials, eliminating manual handling.

- Materials move directly into the drying tunnel, significantly reducing drying time.

✅ Fast & Precise Adhesive Spraying

- The high-performance G9 spray gun offers adjustable spray width from 15mm to 200mm, ensuring uniform, smooth adhesive coverage.

- The system can be equipped with a second spray gun, allowing for the use of multiple adhesive types simultaneously or integrating manual spray guns for specialized applications.

✅ Smart Drying Tunnel – Reduced Waiting Time

- 100cm insulated drying tunnel, with adjustable temperatures up to 110°C, ensuring fast and effective drying in all weather conditions.

- The internal air recirculation system optimizes energy consumption, reducing electricity costs while maintaining high drying efficiency.

✅ Powerful Vacuum System – Cleaner Work Environment

- High-powered suction motor keeps materials stable during spraying, even for lightweight products.

- Eliminates adhesive dust in the air, keeping the work area clean and safe.

✅ Compact Design – Optimized Space Utilization

- The intelligent temperature control system reduces the required drying tunnel length, making the machine less bulky and space-efficient.

💡 UNMATCHED BENEFITS FOR YOUR BUSINESS

🔹 Increased Productivity: Reduces manual handling, significantly boosting production speed.

🔹 Perfect Adhesive Quality: Ensures even and precise adhesive application for maximum bonding strength.

🔹 Cost Savings: Minimizes adhesive waste, reduces energy consumption, and optimizes labor costs.

🔹 Cleaner Work Environment: The powerful vacuum system eliminates airborne adhesive particles, ensuring a safe workspace.

🔹 Flexible & Adaptable: Easily customizable to meet the needs of various industries.

📊 TECHNICAL SPECIFICATIONS

- Chain conveyor length: 210 cm

- Drying tunnel: 100 cm, max temperature 110°C

- Spray gun: G9 (adjustable spray width 15mm – 200mm)

- Adhesive tank capacity: 10 liters (Teflon-coated stainless steel)

- Suction motor power: 3050 m³/h

- Voltage: 400V AC | Power consumption: 4500W

- Machine weight: 480 kg

- Dimensions: 2.40m x 1.95m x 2.00m

📞 CONTACT US NOW – EXPERIENCE CUTTING-EDGE GLUING TECHNOLOGY!

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

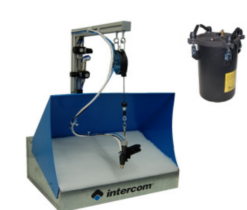

Item description: A3.2

Automatic bonding system, equipped with a 60 cm insulated drying tunnel with internal circulation of air to minimize the consumption; spray gun model G9 with jet adjustable from a cone shape of 15 mm up to 200 mm, modular conveyor belt 210 cm with chain, Teflon stainless steel adhesive tank suitable for 5 Kg and 10 kg bags, aspiration equipped with a powerful aspiration motor with automatic air control system which increases and decreases the force of suction depending on the cleaning level of the filter.

It is also possible to add a second aspirator.

The operator places the materials on the padded carpet of the conveyor belt which automatically brings the materials under the spray gun where the adhesive is applied in a uniform way.

Afterwards the materials go inside the drying tunnel for quick drying of the adhesive under any climatic condition.

At the tunnel exit the materials are ready to be coupled.

Thanks to this system, the materials are not displaced so there are no idle times due to the manual management of these working phases.

The aspiration system has been designed to prevent even the lightest materials from moving due to the air coming out from the spray gun.

Thus, it guarantees the total absence of fine dust particles of adhesive around the machine.

The conveyor belt with chain guarantees an efficient moving process even when the filter becomes heavier due to the adhesive being filtered.

This perfect temperature control inside the oven results in reduction of drying times and therefore, we have managed to design a machine of reduced length resulting in less space occupied by the machine in the working area.

Specific:

| Capacity m3/h: 3800 | Volt: 400 Vac | Prevalence: 1200 | Air lt/min: 180-200 | Bar exercise: 7 |

| Decibel (dB): 78 | Watt: 9000 | Hertz: 50-60 | Ampere: 15-25 | Average consumption: |

| Gross Weight kg: 552 | Tare Kg: 2 | Lenght mt: 2,30 | Height mt: 2,00 | Volume m3: 9,68 |

| Net Weight kg: 550 | Width mt: 2,20 | Usable Depth: 180 x 220 | ||

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)