Comelz AURELIA: a complete digital solution for cutting eco system

The complete software solution for digital production

- SECTORS: Leather goods, Footwear, Textile, Automotive

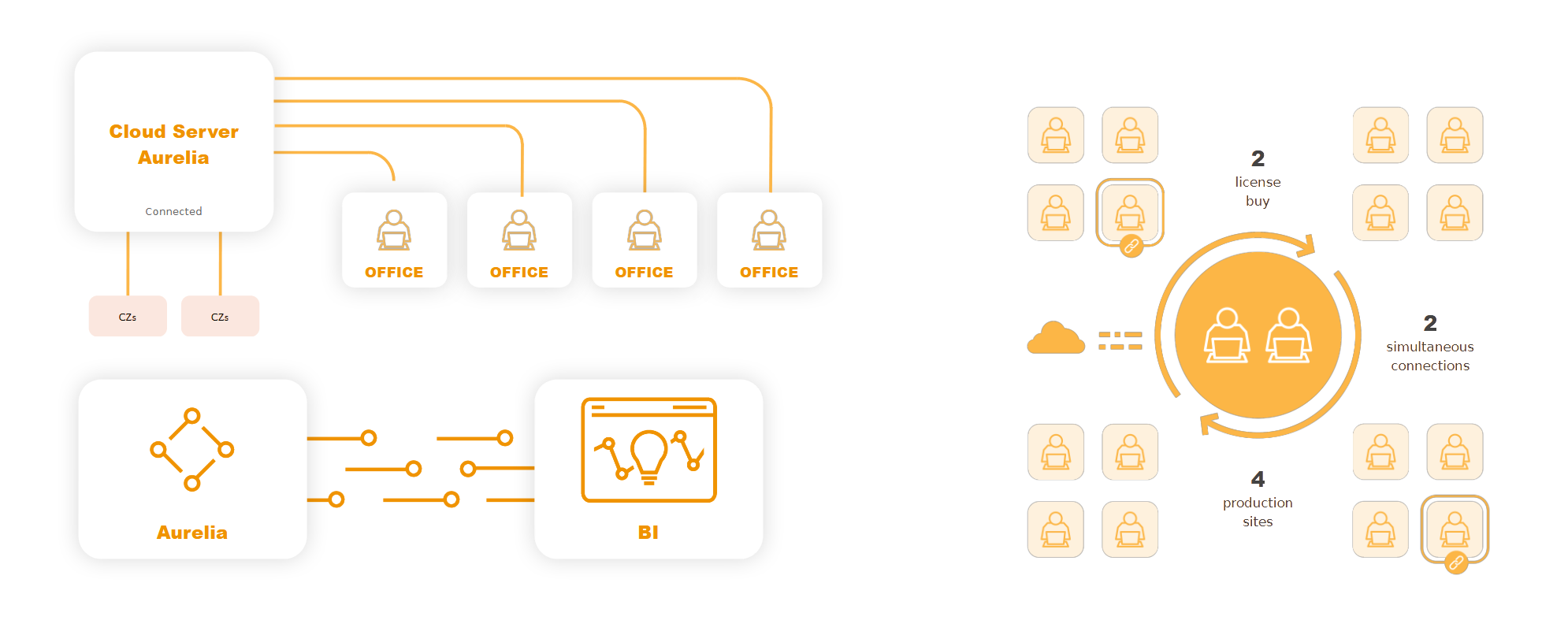

- CONFIGURATIONS: Cloud based, ON- Premise

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

It is a very advanced complete software to manage and control your digital production from the patterns design to the cutting

AURELIA IN A NUTSHELL

- Server software: Your data in your network, with Comelz software security (certified yearly by a third party security company).

- Ready to use: Bring your own server (or VM) from your IT department, or purchase one of our ready-to-use Aurelia Appliances.

- Floating license: Use Comelz software up to a maximum number of concurrent users, with no USB dongle: Caligola, Cleopatra, Network Plotter, Calcon.

- Integrated with the major industrial ERP software: Already existing modules for SAP, Geasoft, Stealth3000, Easysystem, wTrendy, Applinet, others.

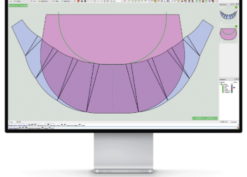

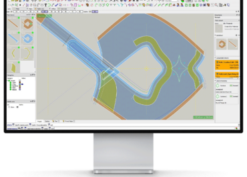

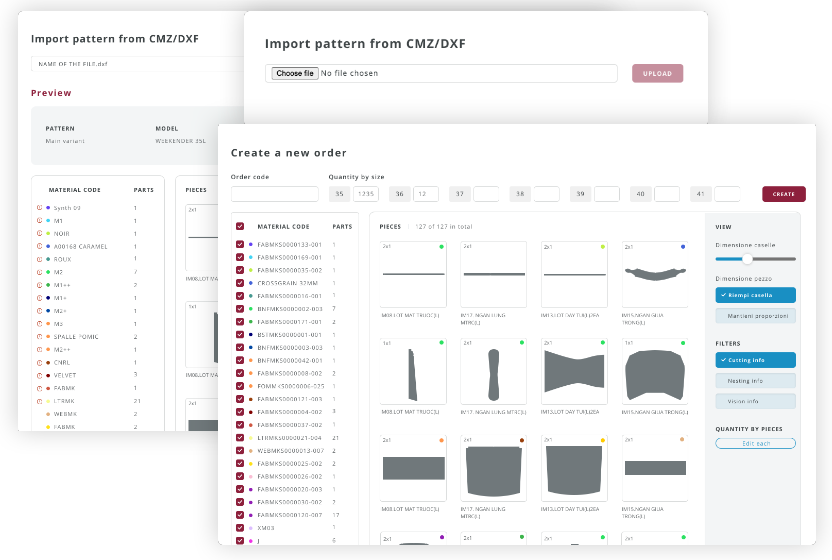

From the patterns to the cutting

- Central repository of patterns: Compare the actual time / consumption for each pattern with the standard. Access from anywhere, from the office, from a tablet.

- Costing for all patterns: Get realistic consumption estimates, with the proven Comelz nesting technology; Use your own hides or define new ones, to simulate lots yet to be purchased (Hide Editor);

- Offline markers for synthetic (Marker Maker): Manual placement, or automatic with Comelz nesting technology

- Send orders to machines: Send orders to each machine directly from the office / ERP (Industry 4.0).

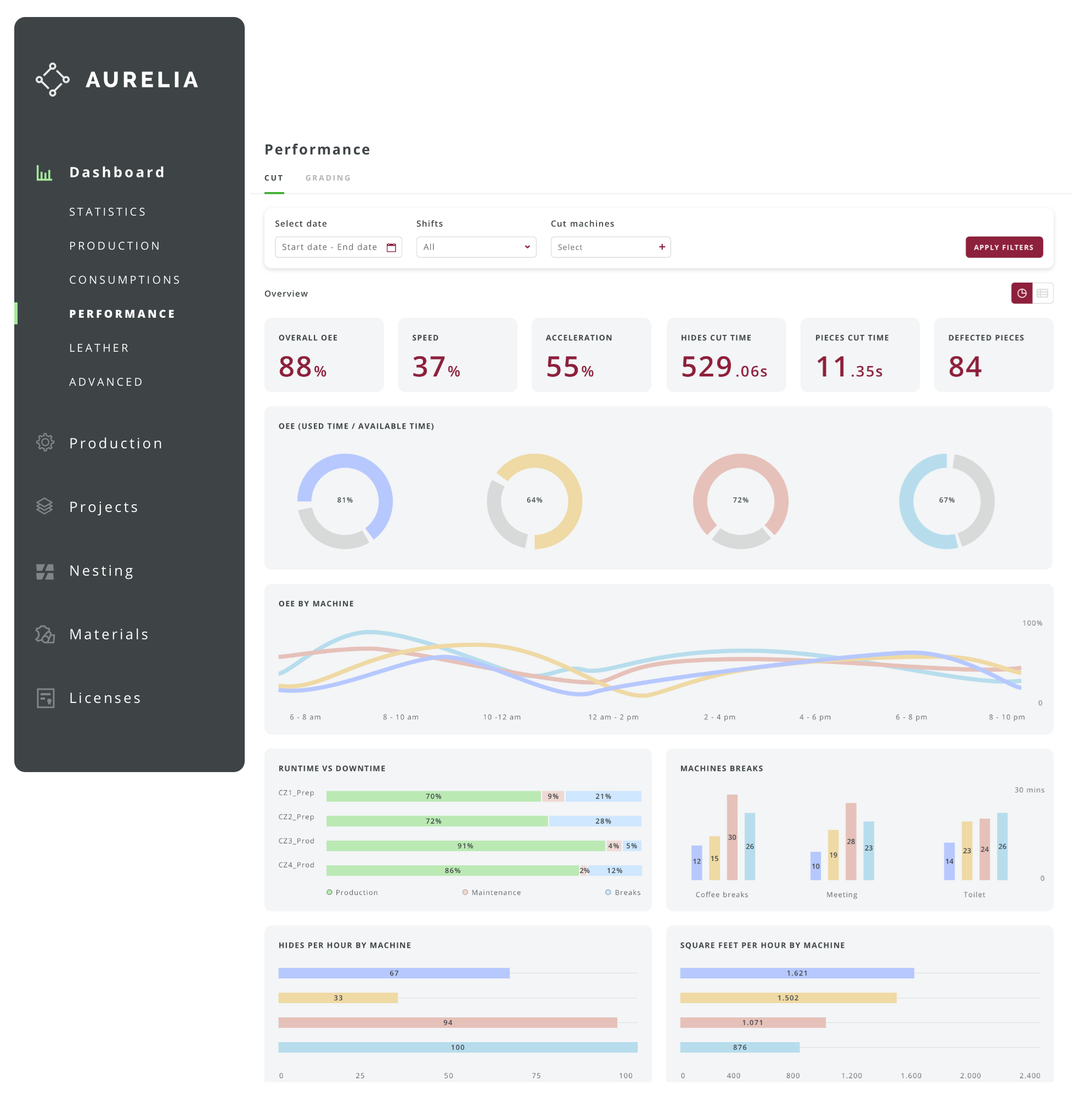

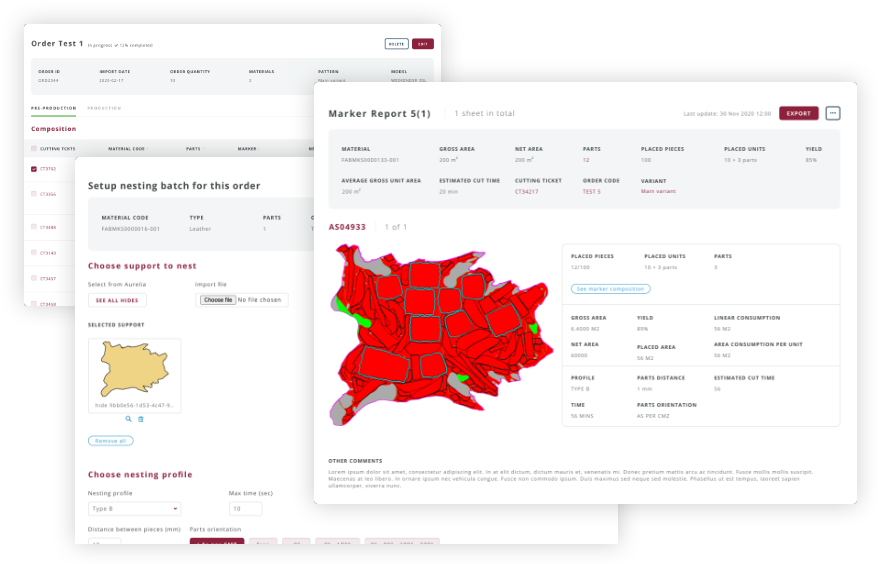

Production Data

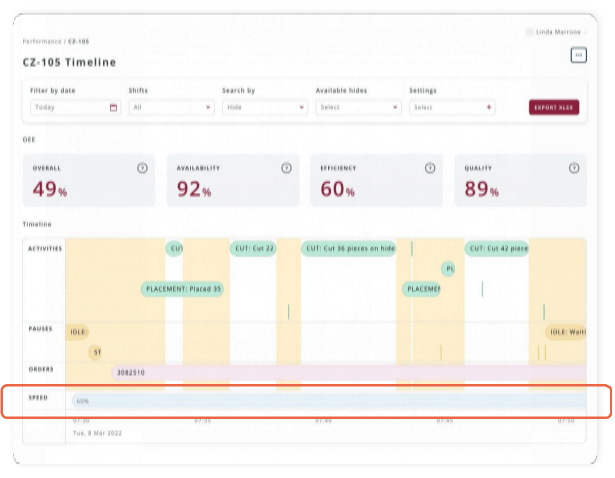

- Analyse your production history: Find the order mixes which minimize production cost, and highlight workflow inefficiencies.

- Train operators to use machines at their best: Inspect your machine activity minute by minute from the office, and improve your workflow.

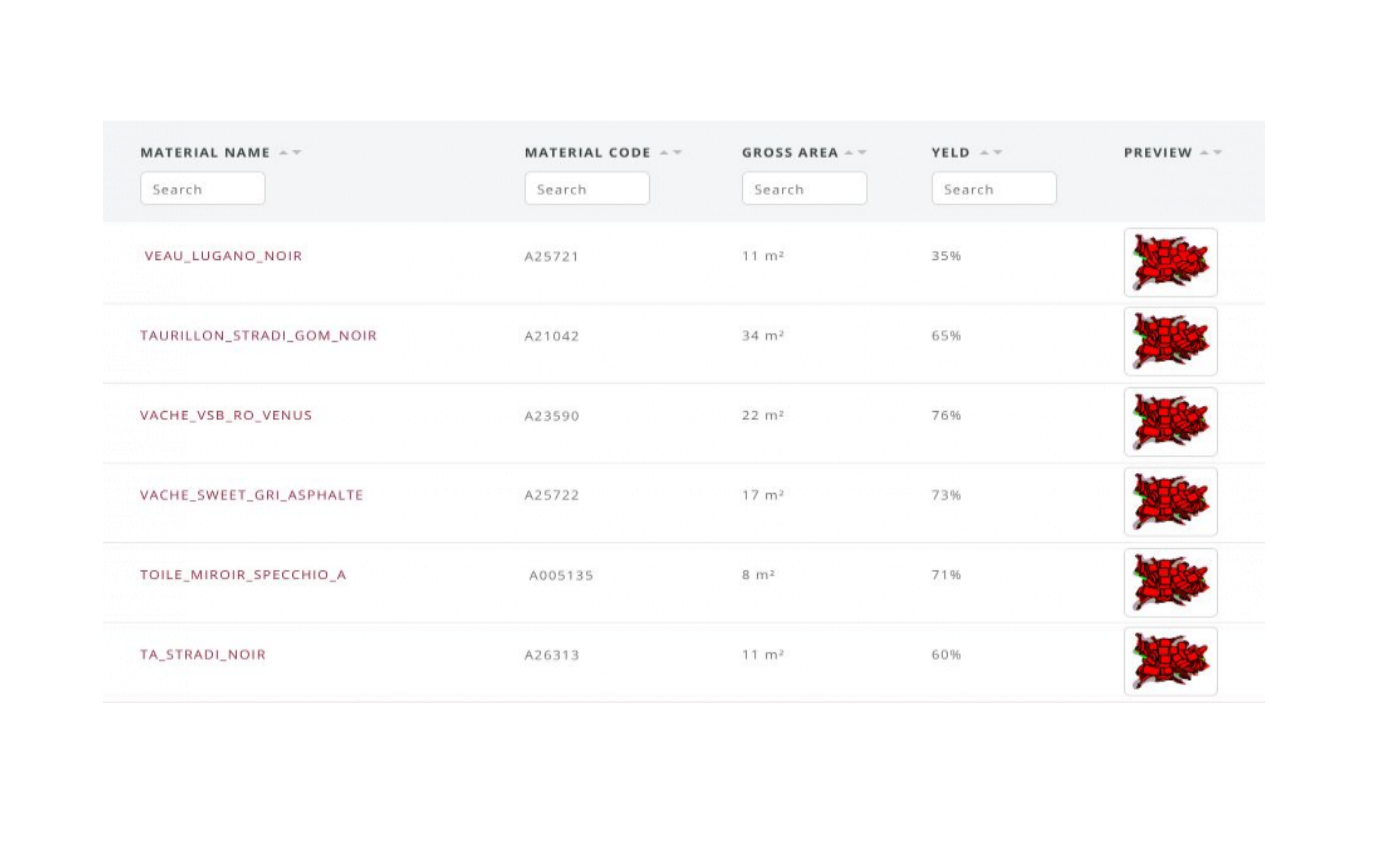

- Tannery analytic report: Routinely check that each tannery bills you a gross in line with the effective area.

- Reasons for recut breakdown: Analyze the most frequent reasons for which operators declare recut, and act on them.

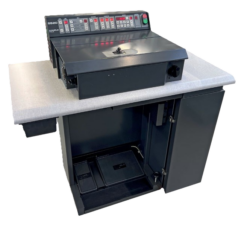

Machine management

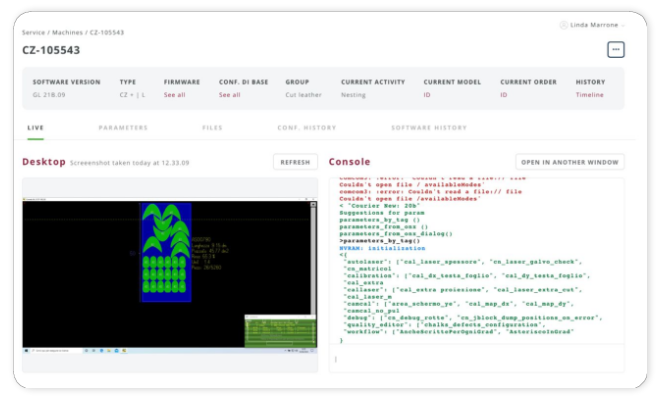

- Remote control of machine configuration: Use a single configuration over the whole production line. Sync configuration on machines directly from the office.

- Centralized material repository: All operators can use the same material settings.

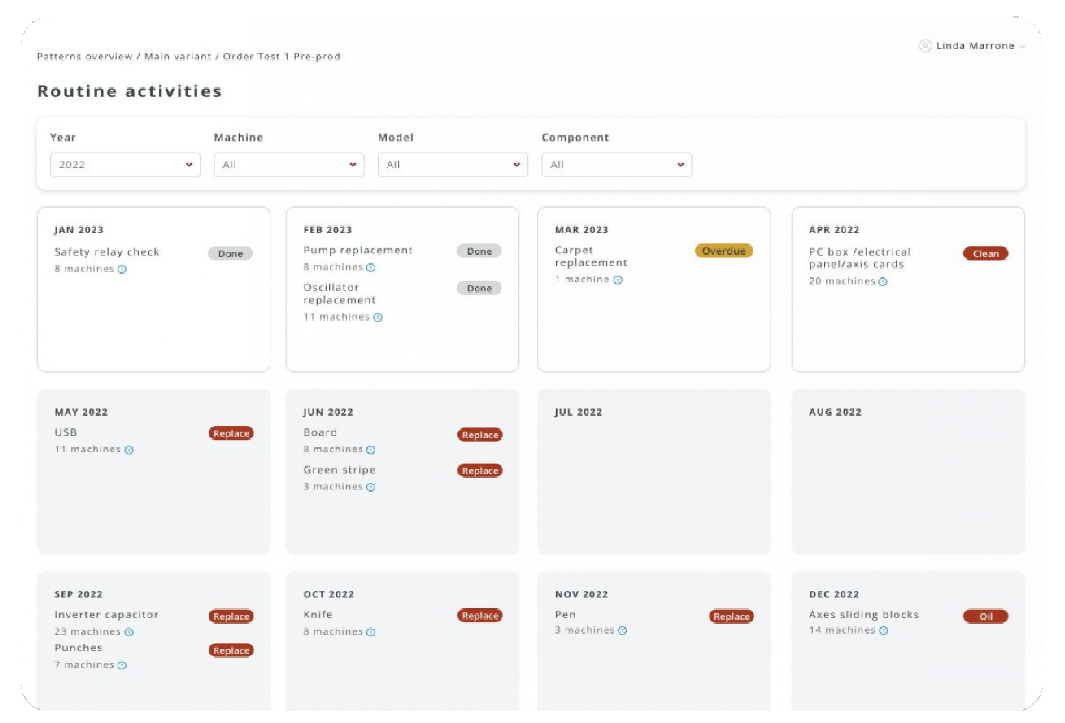

- Preventive machine maintenance: Get notifications for maintenance and list of parts required to maintain your machines.

- Remote control machine: Interact real-time with the machine desktop without stopping the operator’s work.

Find the right fit for your business

FAQ

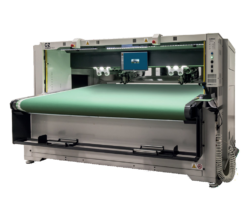

What types of cutting machines do you offer for the shoes and leather goods industry?

Cutting edge solutions from Comelz with the CZ Series and CZ Plus Series can fulfil vary requirements from your production in both leather and synthetic cutting. With state-of-the art multi-tools cutting heads, the production with Comelz technology can be increased double efficiency compare to traditional cutting way. Vu Long Company provides a variety of Comelz brand automatic cutting machine products to always ensure meeting customers' production needs.

How to maximize the material usage?

Material utilizations is the important key of footwear and leather good industry which can be push to the limits with Comelz auto nesting technology. Thank to the powerful nesting engine, production with Comelz auto nesting can reach the leather saving up to 12% depend on the material types and models.

Training and After sale service

On-site training is included in the new machine installation package. Vu Long also provides annual training and updates to all customers who are using Comelz machines and have maintenance contracts. Vu Long ensures prompt delivery and after-sales service at competitive costs to ensure customers can maintain production with ease.

What are the safety features of Comelz cutting machines?

All Comelz technology are complied with the CE standard and validated by TUV. See more...

How to carry trials and testings

Vu Long always welcome all customers to visit the showroom at 437 Tan Son, Ward 12, Go Vap District, Ho Chi Minh city to evaluate the new technology and performance tests for the latest machines from Comelz.

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)