A footwear manufacturer achieves Significant Leather Savings with Comelz Auto Nesting.

Challenge:

A leading global footwear manufacturer and key partner for Nike, faced the constant challenge of optimizing material usage, particularly leather, a significant cost driver in shoe production. High-volume manufacturing amplified the impact of even small amounts of leather waste, making efficiency a critical concern. Existing cutting processes struggled to maximize leather yield while maintaining production speed and handling the complexity of diverse shoe styles. They sought a solution to enhance both cost-effectiveness and operational efficiency.

- Rising Material Costs: Leather, a significant expense, impacting profitability.

- High-Volume Production: Small waste percentages translate to large financial losses.

- Complex Shoe Styles: Diverse designs and sizes complicate efficient leather usage.

Solution:

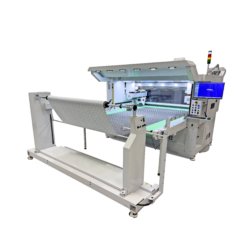

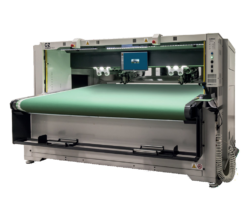

Partnered with Comelz to implement their advanced auto nesting technology. This software solution offered intelligent nesting algorithms capable of analyzing pattern pieces and dynamically optimizing their placement on leather hides. Real-time adjustments based on hide shape and quality, coupled with a user-friendly interface, empowered operators to quickly create efficient layouts. Seamless integration with the existing cutting machines, including leather defect management capabilities, ensured a smooth transition and rapid return on investment.

- Intelligent Nesting Algorithms: Optimizes pattern placement for maximum yield.

- Real-time Adjustments: Adapts to leather hide shape and quality dynamically.

- Seamless Integration: Works with existing CAD/CAM and cutting machines.

Result:

The results were impressive. the factory achieved a significant [insert quantifiable percentage, e.g., 8-12%] reduction in leather consumption, leading to substantial cost savings. This improvement stemmed from the optimized pattern placement, minimizing waste and maximizing yield. Beyond material savings, the automated nesting process streamlined the cutting workflow, boosting production speed and throughput. The intelligent algorithms quickly generated optimal layouts, reducing manual nesting time and freeing up valuable resources. Furthermore, the precise nesting and cutting ensured consistent quality across all shoe components, reinforcing the reputation for excellence in manufacturing.

- Substantial Cost Savings: Reduced leather consumption translates to significant financial gains.

- Increased Throughput: Streamlined workflow and faster cutting process.

- Consistent Quality: Precise nesting and cutting ensure high-quality components.

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)