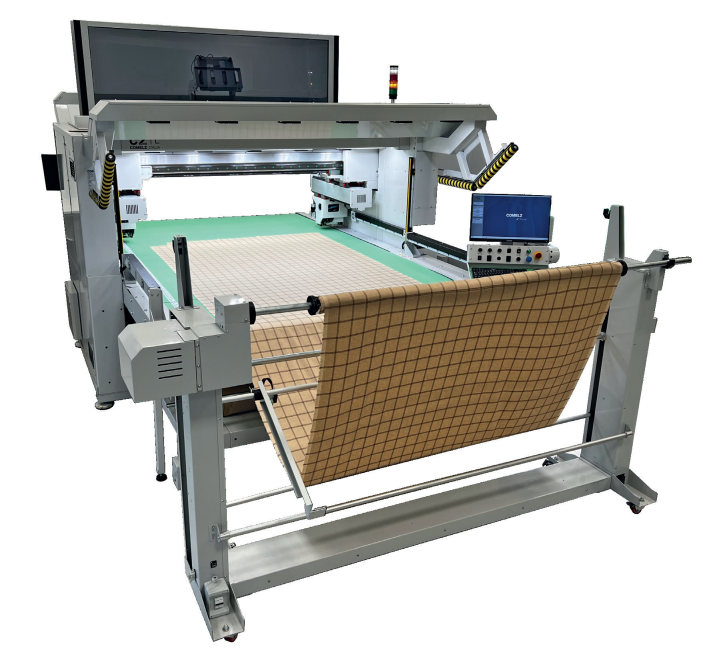

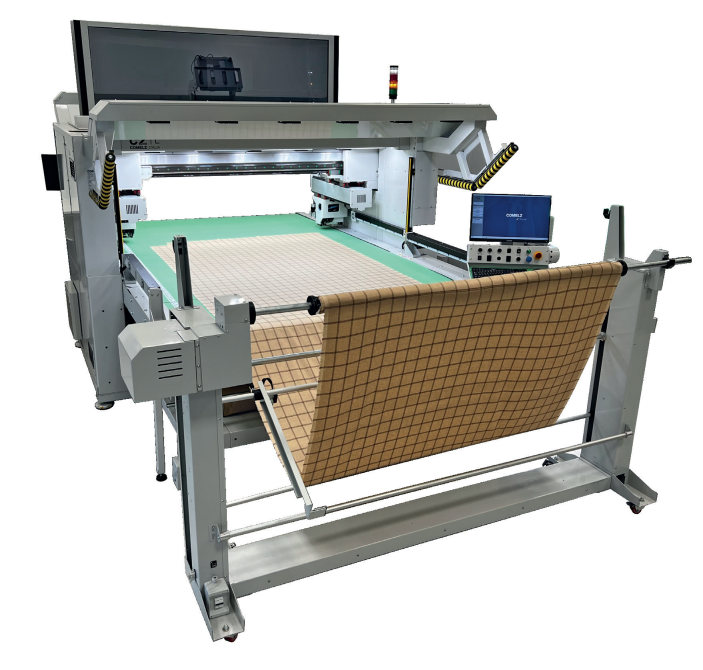

The ultimate cutting machine CZ Plus Serie: CZ+/L Extend

- SECTORS: Leather goods, Apparel

- CONFIGURATIONS: pattern fabric cutting with vision

- Work area: 1800 x 900 mm oscillating blade

- Work area: 1900 x 900 mm rotating blade

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

The CZ Plus series: CZ+/L Extend is the unique pattern fabric cutting system from Comelz with advanced vision technology and truly innovative cutting machine for apparel industry.

CUTTING WITH HIGHEST QUALITY & PRODUCTIVITY

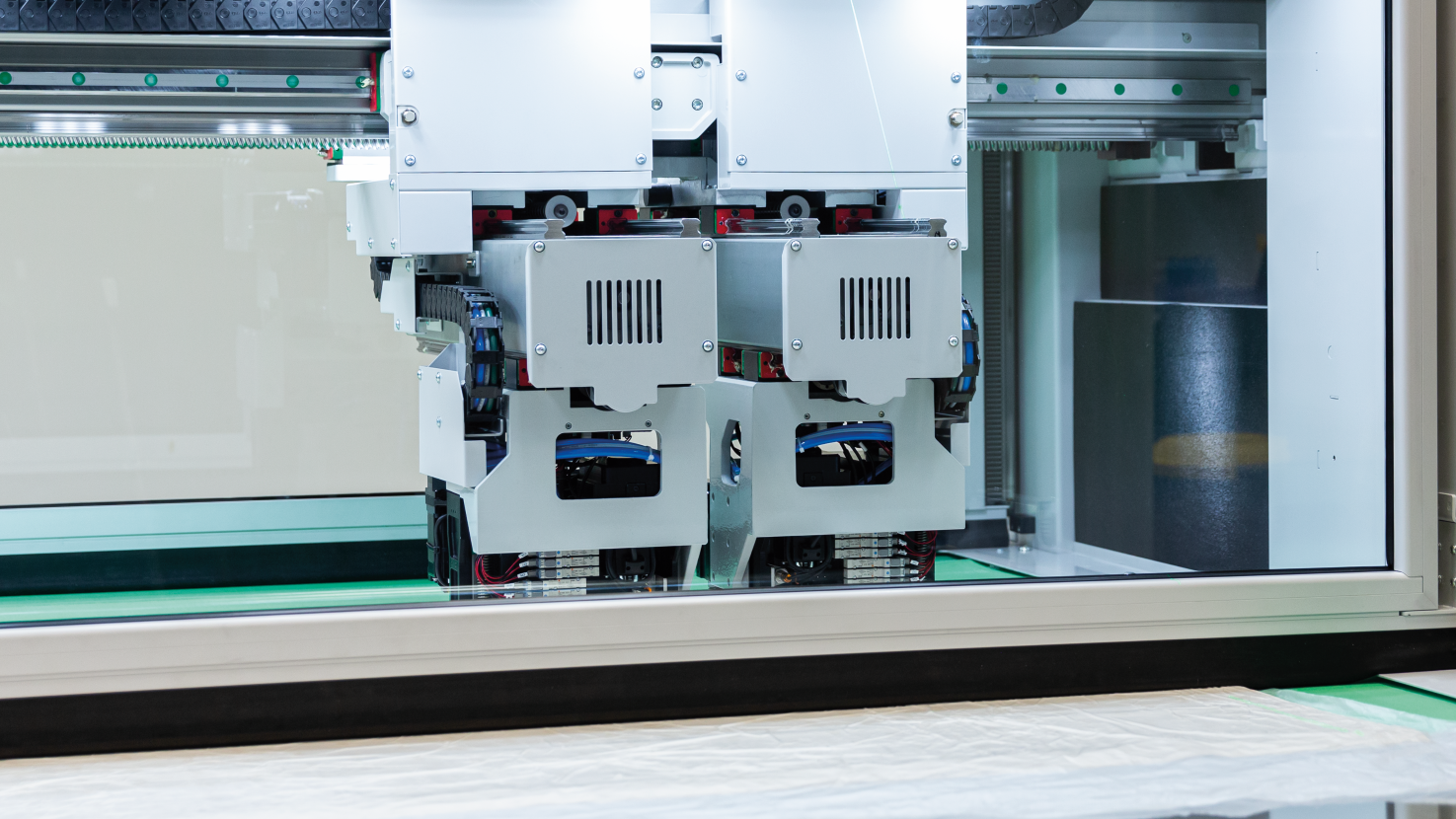

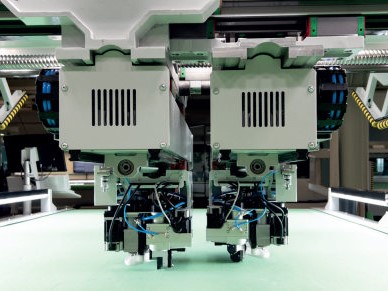

The structure of CZ+/L Extend is stronger: the cutting speed gets to limit not possible before. Therefore, the performances are impressive. Interlocking carriages bring the two cutting units to touch each other while cutting allow two cutting heads operating simultaneously in order to significantly increase productivity.

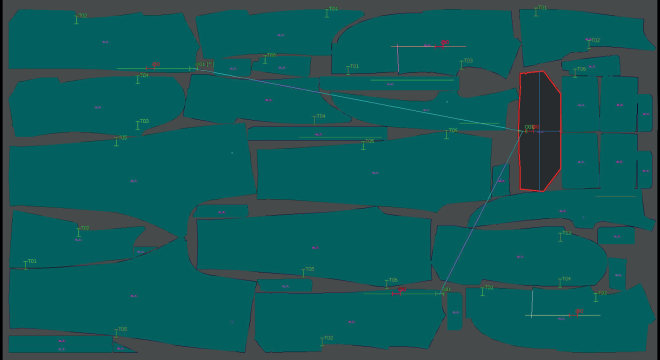

START OF THE ART SOFTWARE

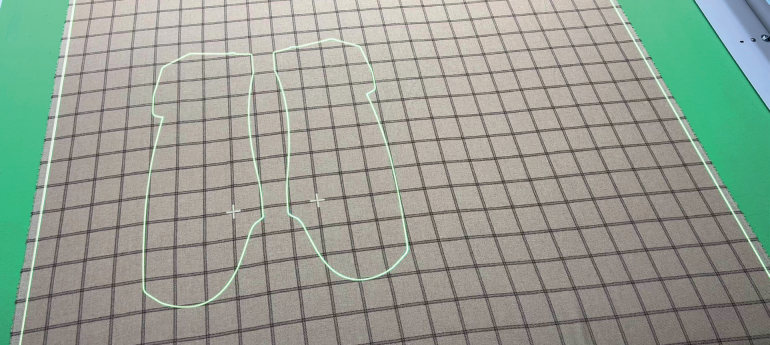

• Automatic nesting: For striped/checked or repeated fabrics with patterns, a fully automatic nesting is available that optimizes the material yield (a special feature is also available that allows, while optimizing the yield, several pieces to be placed next to each other to avoid typical problems due to step variation). Nesting is carried out during the cutting of the previous garment and therefore does not involve machine downtime.

• Automatic material deformation management: Standard system with error minimization at various points.

• Advanced CFSS system (Comelz Fabric Straightening System) exactly replicates the results of fabric straightening with a needle table, eliminating its limitations.

• CFRS (Comelz Fabric Resizing System) for automatic management of “material drop” and “material step change” (with different settings for warp and weft).

• CFDS (Comelz Fabric Defect System) for defect management. Defects can be entered manually using the laser projection system. The nesting, carried out directly on the machine, is modified in real time to avoid any fabric defects (minimizing material material waste). Obviously the machine software allows also cutting of plain-color fabrics with excellent productivity levels.

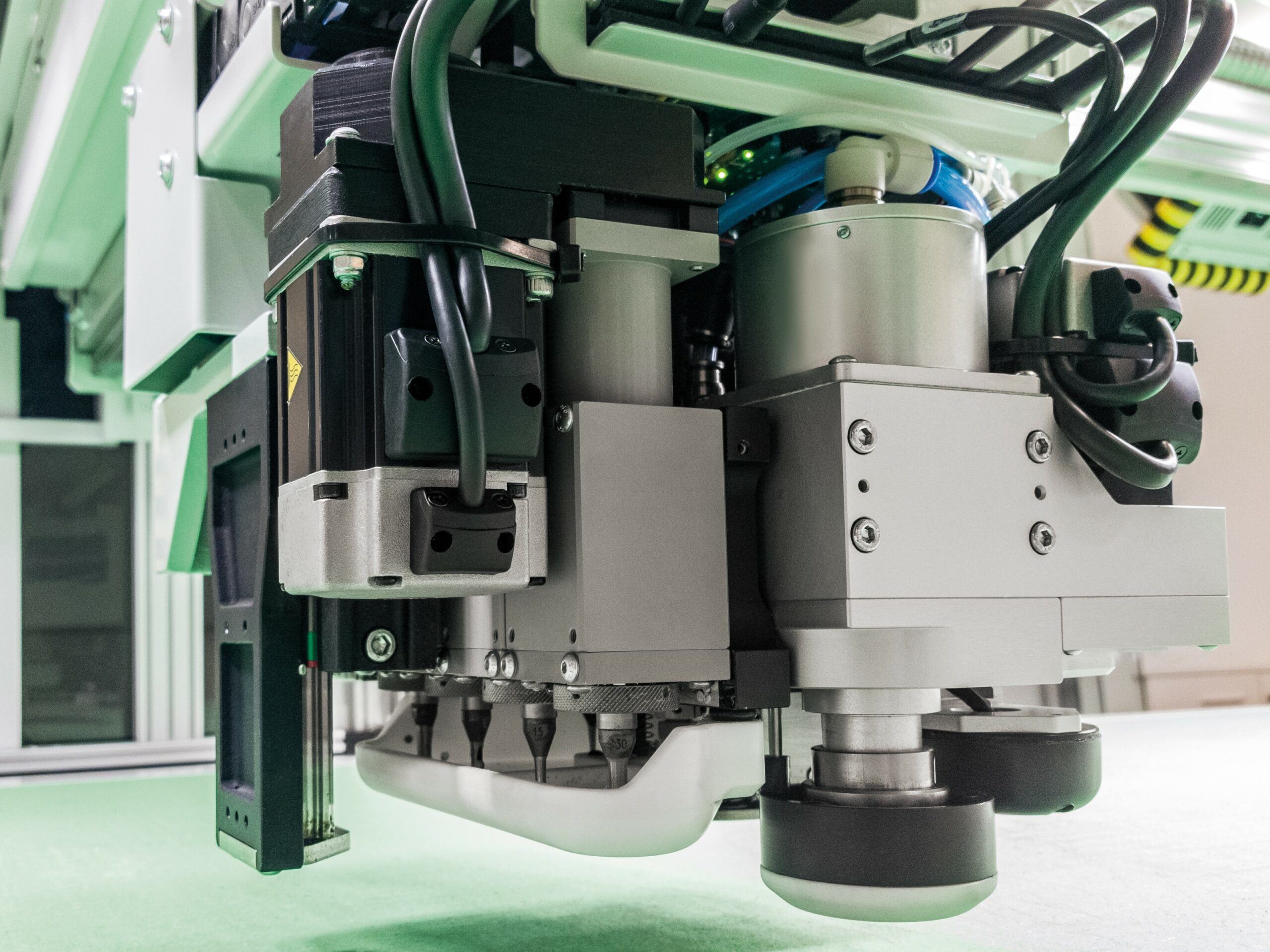

State-of-the-art multitools cutting head

The machine, even in the standard configuration, has most of the same state-of-the-art features available on Comelz top of the line machines. Each cutting head of the CZ+/L Extend is equipped with a cutting tool (decagonal blade or oscillating blade), a scoring pen and as many as five tools for holes of various diameters (including heated needle).

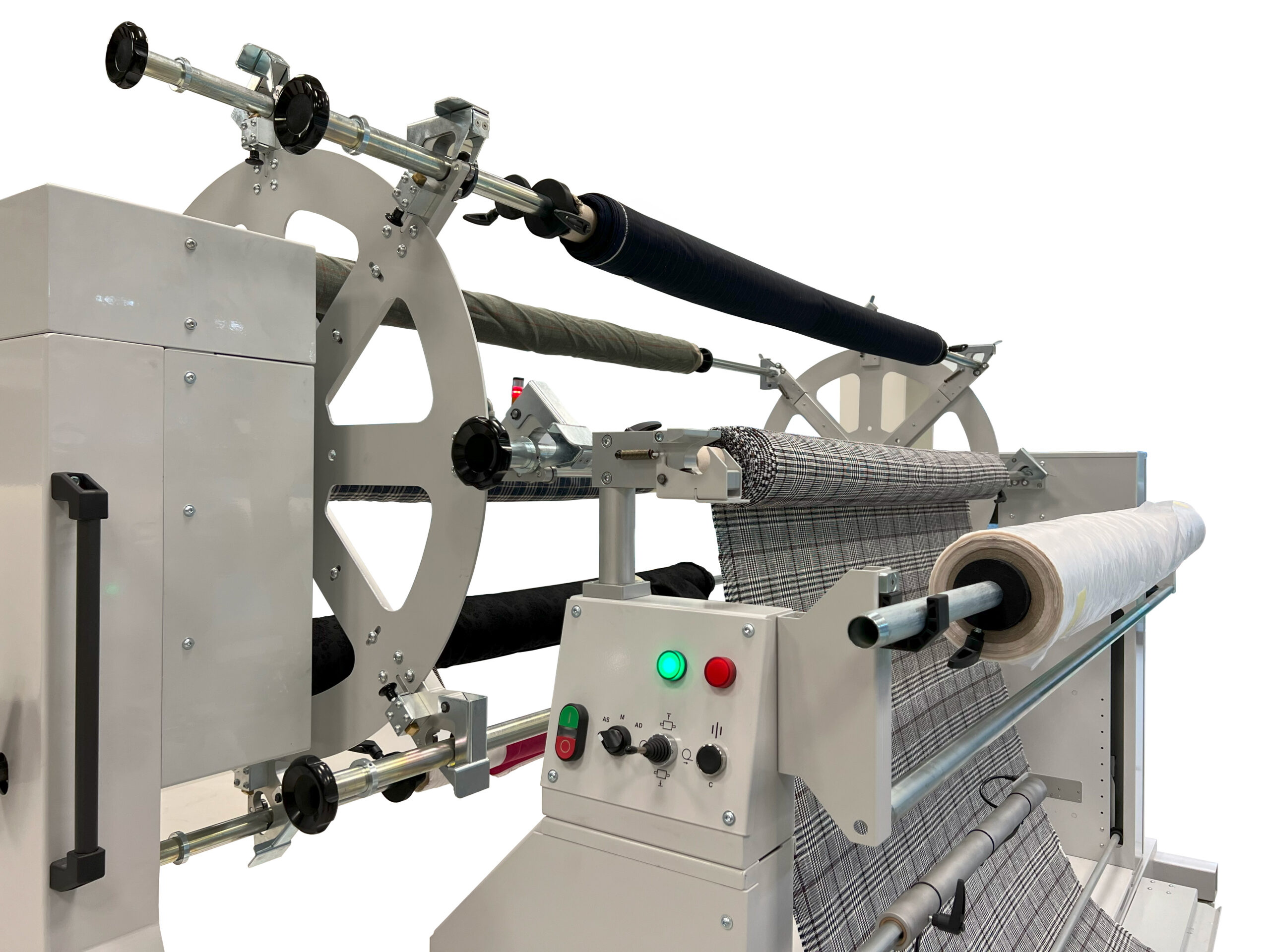

MATERIAL LOAD WITH ACTIVE UNWINDER

Together with the CZ+/L Extend cutting system, the material is loaded using a fixed roll holder integrated in the machine or an optional “tension free” active unwinder with automatic selvedge alignment, quick roll change and prepared for external loading system (RA).

ENVIRONMENTALLY SUSTAINABLE SOLUTION

- Suction controlled by inverter and focused only where it is needed (automatic micro-partitioning at 60 sectors / m 2 ).

- CNC is equipped with energy-efficient motors.

- Cutting without the need for underlay perforated paper and overlay plastic film.

- Powerful automatic in-line nesting that exploits the actual height of the fabric, minimize missing material waste.

- Low consumption laser projectors and dimmable LED lighting.

- Very small machine footprint that minimizes space requirements and operating costs.

- “Green plate” certification for the machine. Comelz produces cutting machines using only renewable energy. This results in one of the most environmentally friendly solutions on the market.

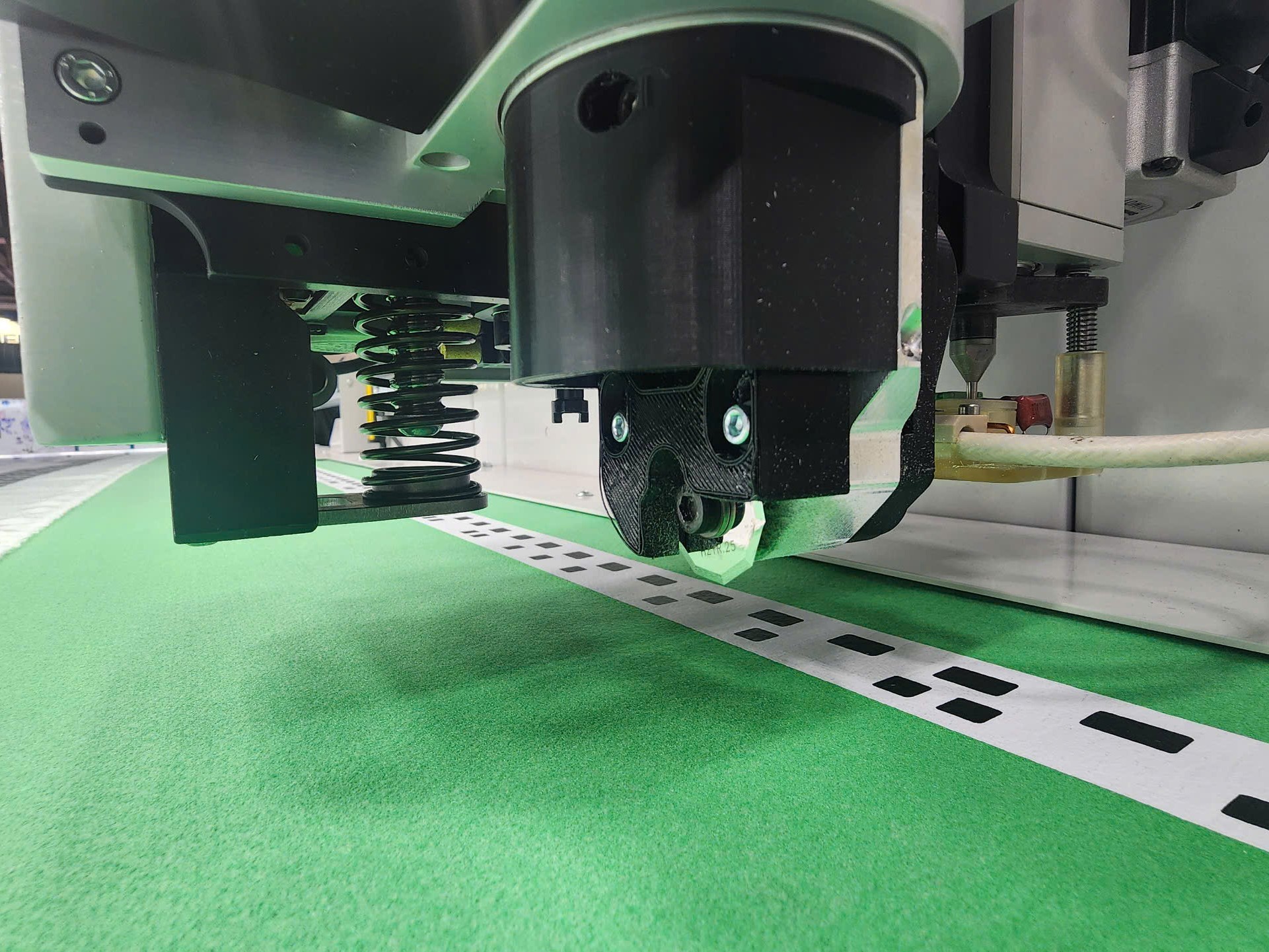

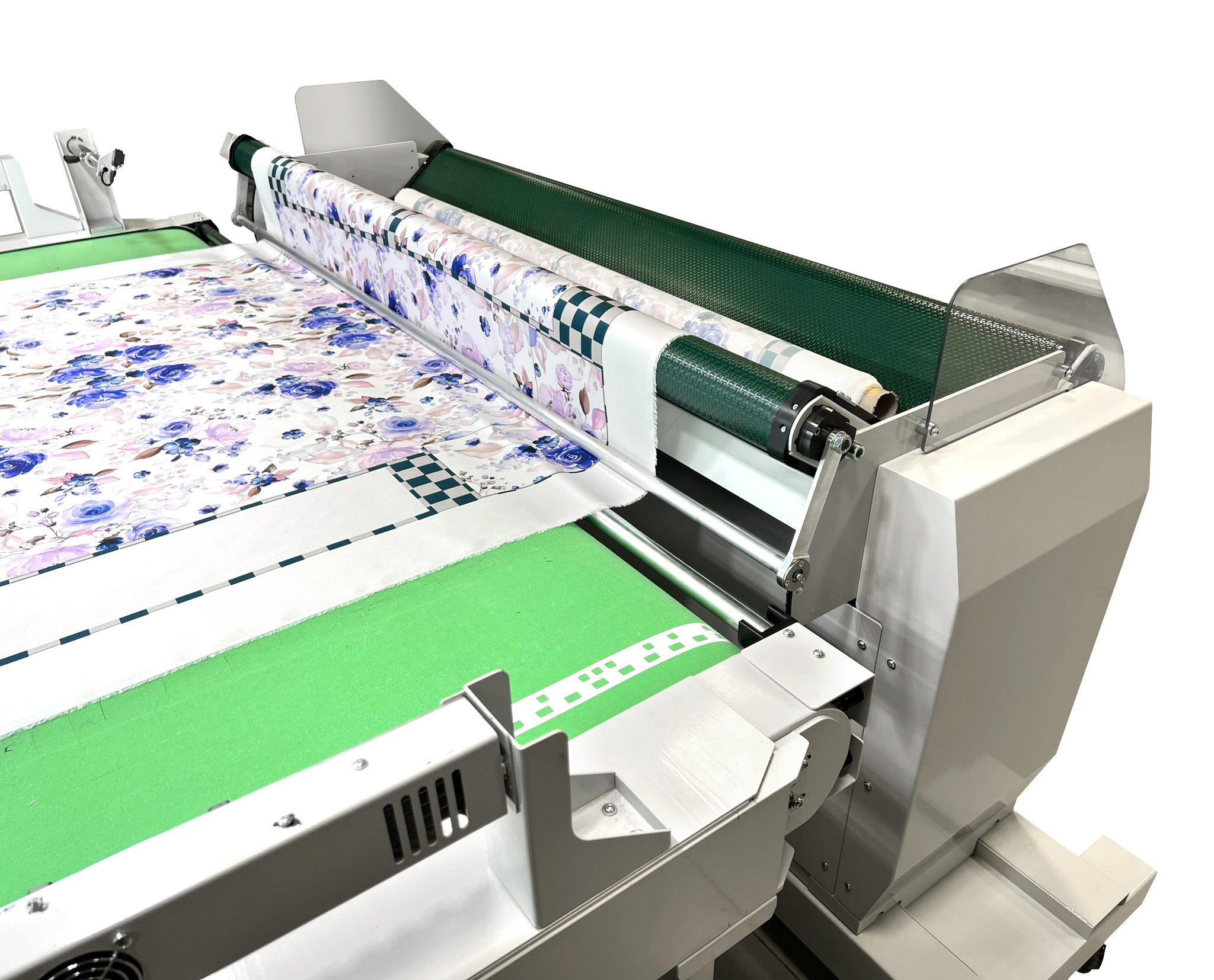

VISION + LIGHTING

Comelz is the only company with a fully proprietary advanced vision system (from the design and production of the cameras, lighting system and the vision software).

Comelz vision system on the CZ+/L Extend includes 12 high-resolution industrial cameras equipped with special lenses to recognize even the most difficult materials. The large number of cameras allows the vision system to be positioned close to the fabric, minimizing the typical problems of systems with few cameras positioned far from the fabric, which are less accurate and have to be recalibrated often.

The field of vision allows nesting of any length to be cut. To be able to read even the most difficult fabrics, the machine is equipped with an innovative lighting system with 32 dimmers and lights from different angles.

PROJECTION

The CZ+/L Extend is equipped with 4 laser projectors and 2 LCD projectors.

The 4 laser projectors are much brighter and more accurate than traditional LCD projectors (about 65,000 dots instead of about 2,000 dots). These projectors can be used for multiple purposes:

• to carry out a manual placement directly on the fabric (for example for cutting samples and very small series)

• to recut pre-assembled pieces.

• to carry out the initial alignment of the rolls

• to project symbols for centering or reference (selvage, straight edge, anchor points)

• The 2 LCD projectors are used to facilitate the collection of pieces by projecting the pieces in various colors according to the chosen setting.

Technical data

| Descriptions | Data |

|---|---|

| Cutting area CZ Plus L Extend (mm) | 1800 x 900 mm oscillating blade 1900 x 900 mm rotating blade |

| Cutting speed | 60 m/min |

| Maximum punching frequency | 600 p/min |

| Air supply | 300 L/min a 6 bar |

| Power supply | 3 phase 400V – 50/60 Hz 3 phase 220V- 50/60 Hz (optional) |

| Maximum power consumption | 20 KW |

Find the right fit for your business

Block "sp-1-faq-block" not found

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)