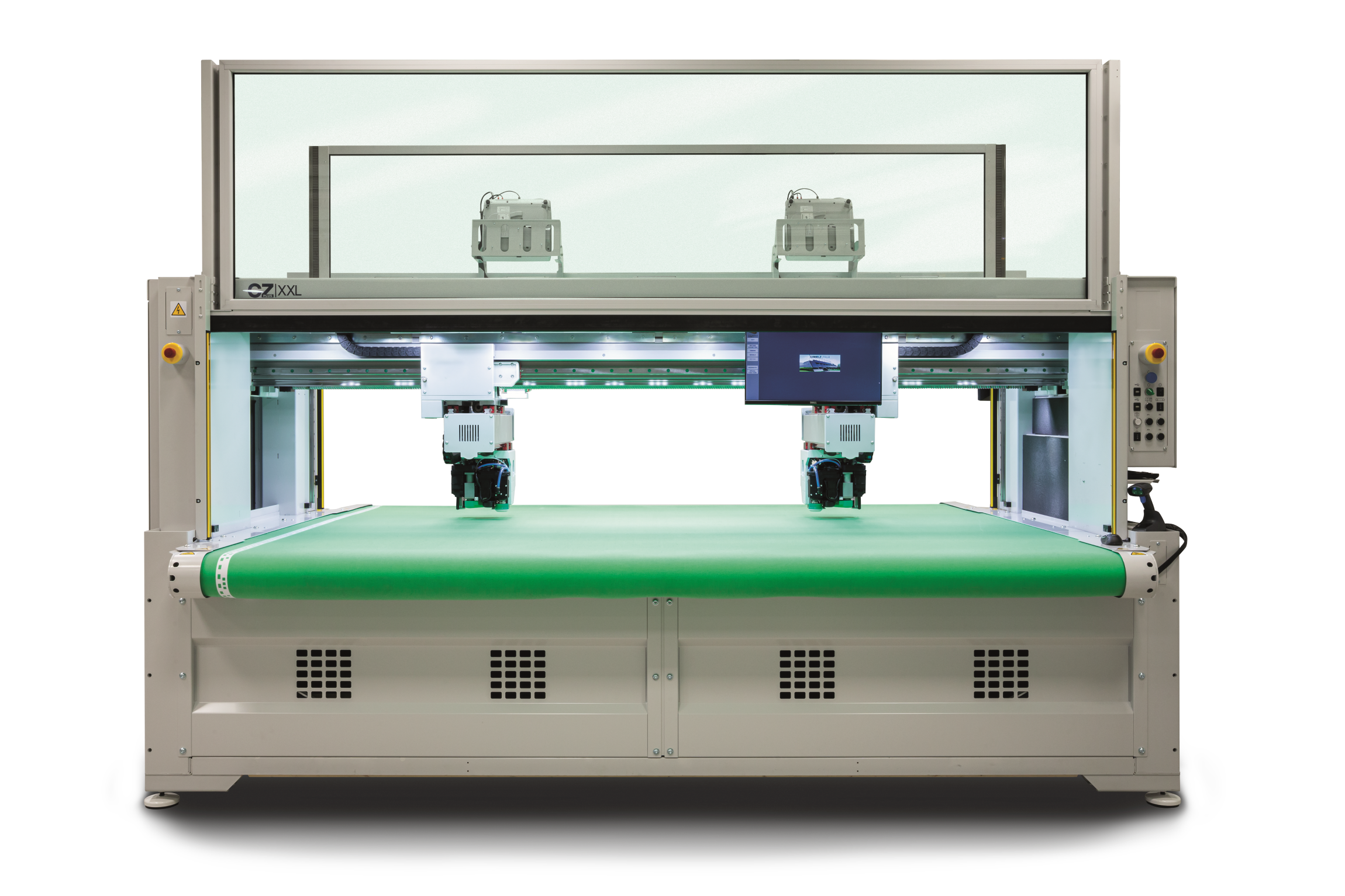

The ultimate cutting machine CZ Plus Serie: CZ+/XXL

- SECTORS: Leather goods, Footwear, Automotive, Apparel and Furniture

- CONFIGURATIONS: multi-ply synthetic cutting (multi-ply spread and multi-roll), leather cutting

- Work area: 3000mm x 840mm

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

The CZ Plus series is the expression of Comelz’s goal to create flexible, versatile though high performing, technologically advanced and truly innovative cutting machines..

CUTTING WITH HIGHEST QUALITY & PRODUCTIVITY

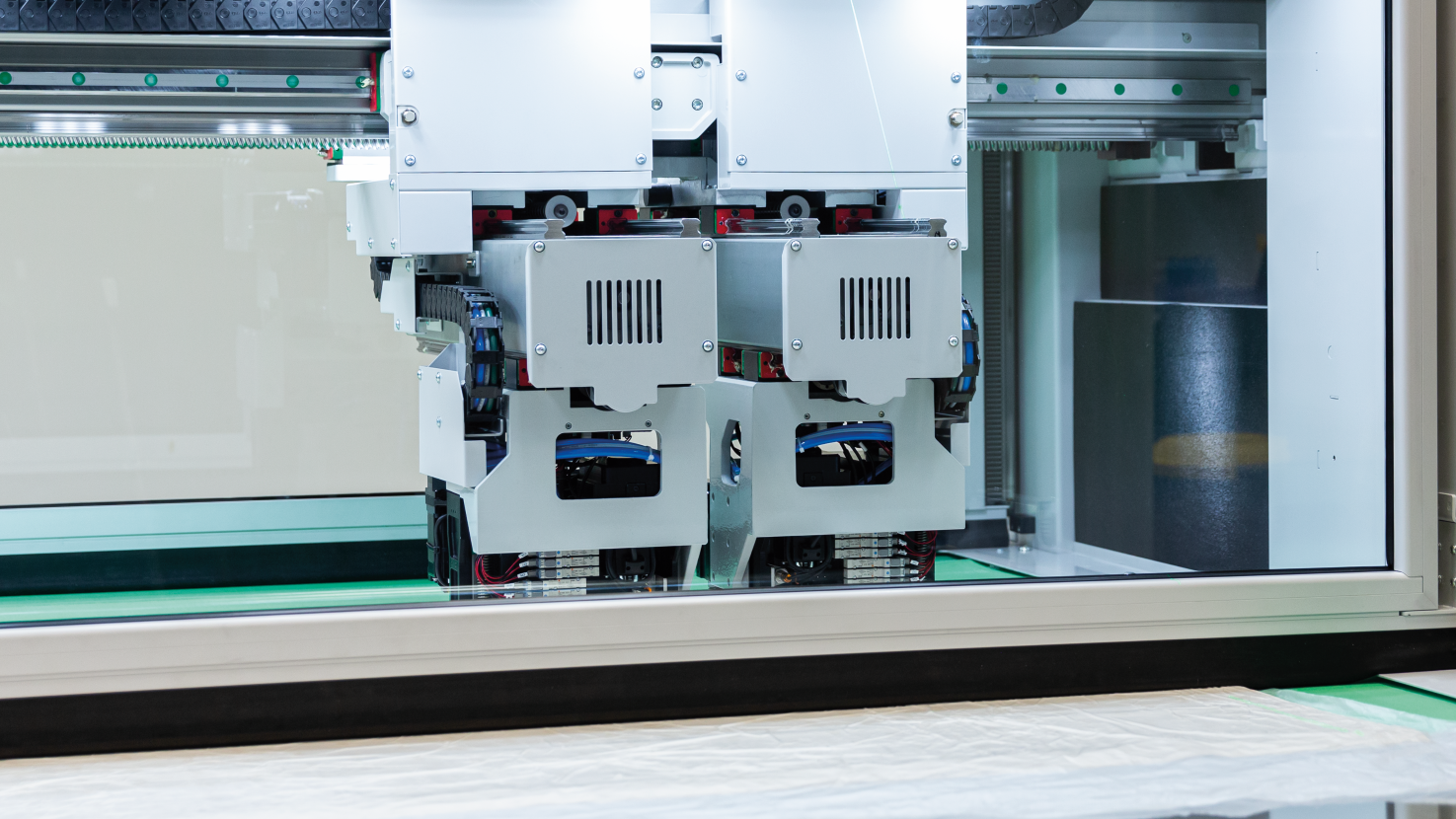

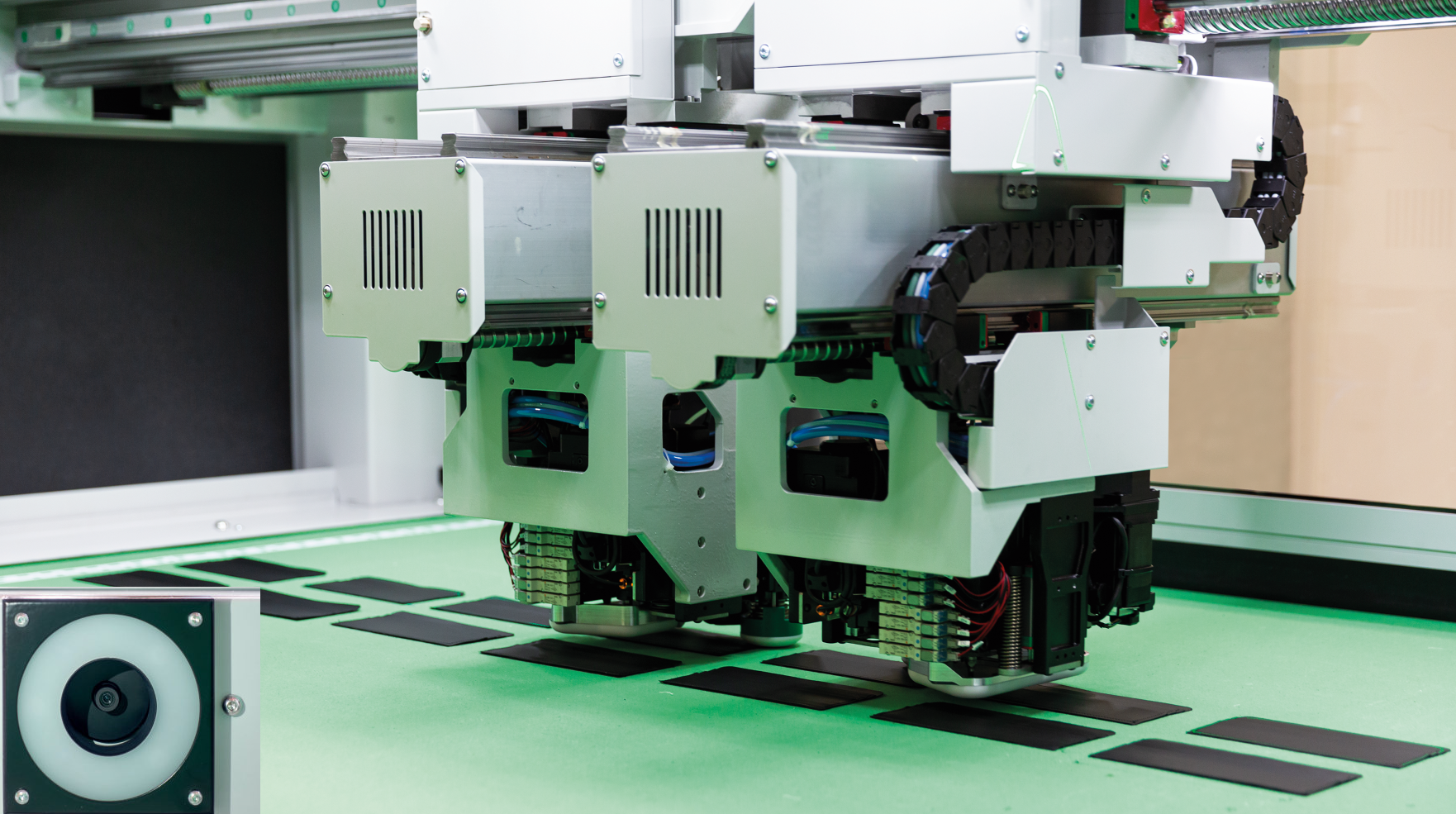

The structure of new machines is stronger: the cutting speed gets to limit not possible before. Therefore, the performances are impressive. Interlocking carriages bring the two cutting units to touch each other while cutting. Machines are equipped with new generation heads. Double head support, new punching units, cutting unit with brushless motor.

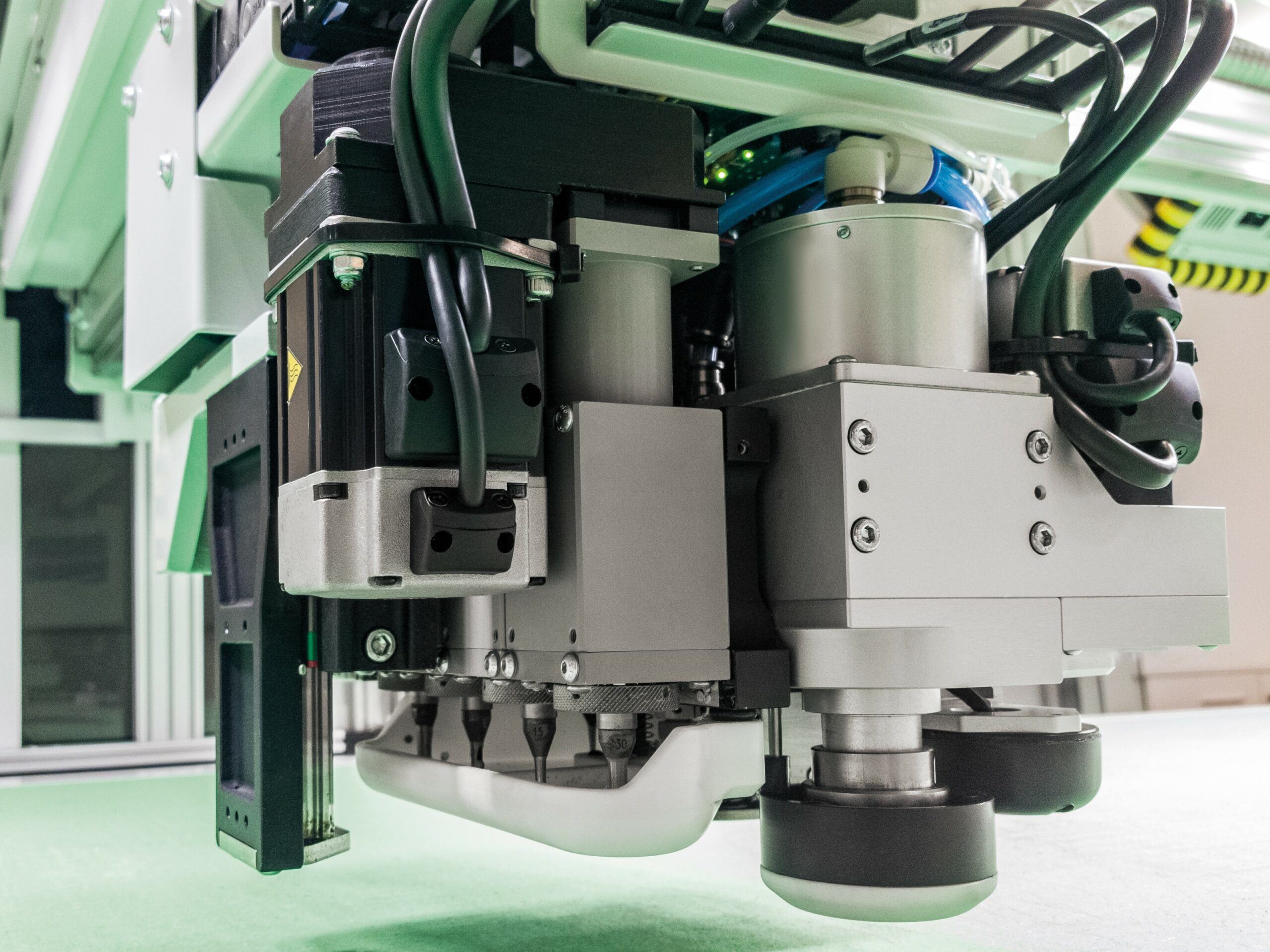

State-of-the-art multitools cutting head

- 7 tool cutting head (high frequency pneumatic knife, 4 independent punching units, pen, pin punch).

- high-end endless screws (in place of more economical drive belts or rack-and-pinion systems).

- micro-partialization system for the vacuum of the cutting area.

- vacuum pump (up to 17.5KW) enclosed in a cooled and sound-proofed area inside the machine

- electronic lubrification system for the cutting unit.

- isolation transformer for protection against most issues on the electric power supply.

- Comelz software for machine control and automatic nesting highly regarded for being user friendly, open, easily interconnected, and scalable.

VISION SYSTEMS FOR MORE INDUSTRIAL APPLICATIONS

With the CZ Plus series it is possible to have the most effective vision system that Comelz ever made in combination with the productivity of the double head machine. CZ Plus equipped with vision can cut textile/synthetic materials with drawings, logos, pre-printed images or roll of engineering mesh or similar. Final trim of pre-assembled parts can be also done.

Technical data

| Descriptions | Data |

|---|---|

| Cutting area CZ Plus XXL (mm) | 3000 x 840 |

| Cutting speed | 60 m/min |

| Maximum punching frequency (for each head) | 600 p/min |

| Air supply | 300 L/min a 6 bar |

| Power supply | 3 phase 400V – 50/60 Hz 3 phase 220V- 50/60 Hz (optional) |

| Maximum power consumption | 20 KW |

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)