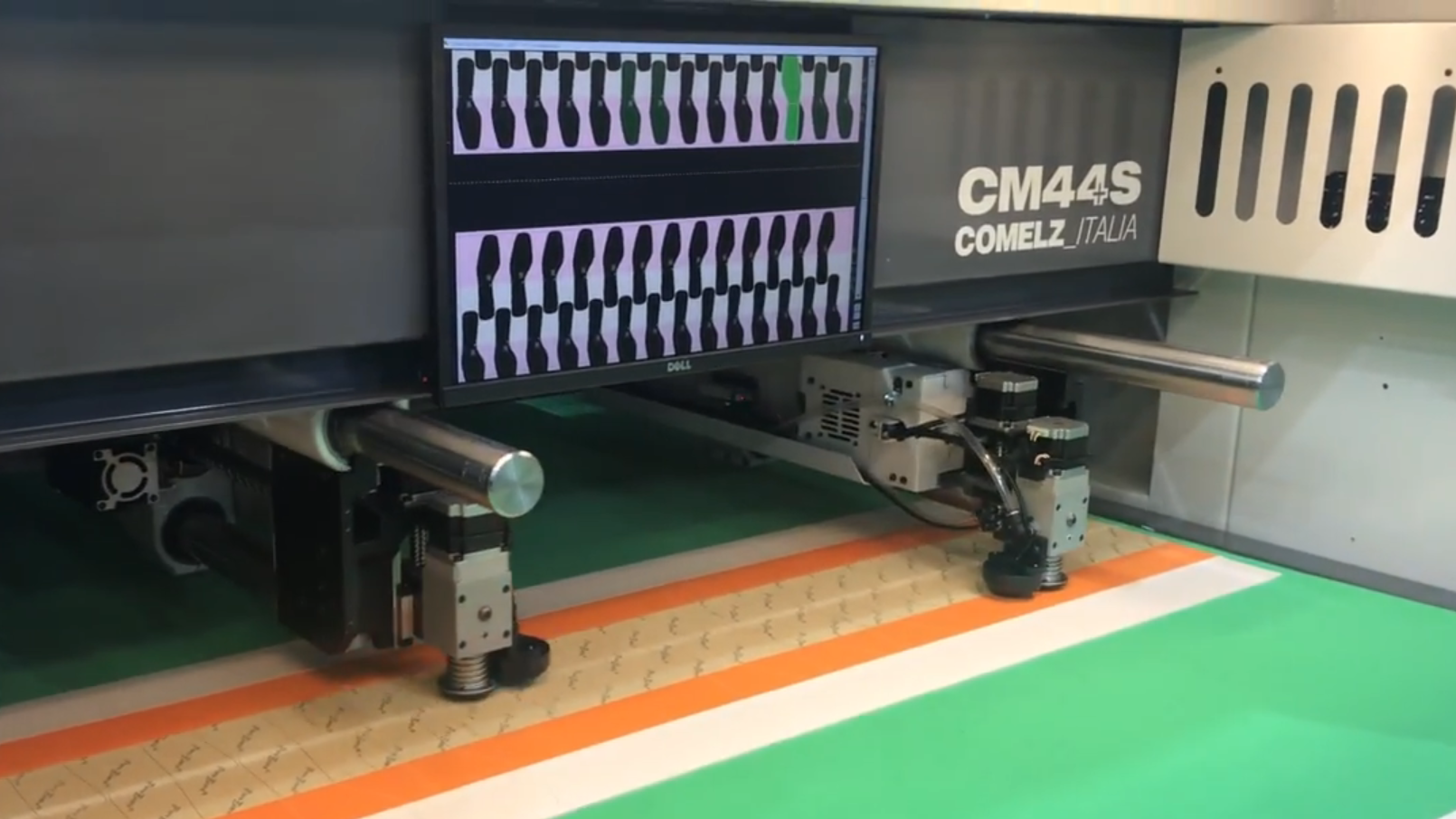

The insole cutting machine Comelz CM44 -trung

- SECTORS: Leather goods, Footwear, Automotive, Apparel and Furniture

- CONFIGURATIONS: multi-ply synthetic cutting (multi-ply spread and multi-roll), leather cutting

- Work area: 1850mm x 840mm

A high productivity system for cutting insoles and soles.

BLADE CUT FOR INSOLES AND SOLES

CM44 is a high productivity system, with conveyor belt and two oscillating blade cutting heads, for cutting without punches of insoles, soles, tips and buttresses on cellulosic material, cellulosic material coupled with reinforcement strips (and / or foam rubber and / or canvas), cardboard for heels, leather, hide, regenerated leather, tunit, salpa, thermoplastic, etc.

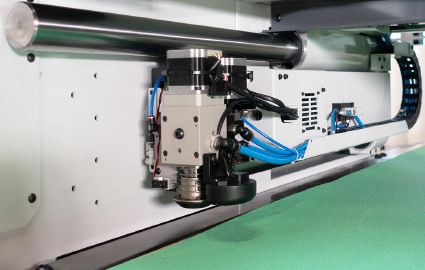

TWO INDEPENDENT CUTTING HEADS

Fast and robust, the two cutting heads with oscillating blade and marking pen operate with independent paths over an area of 1500 mm width and virtually unlimited length, optimizing material consumption and cutting speed to the maximum.

UNIVERSAL AUTOMATIC LOADER

It is equipped with multiple gripping elements with 18 needles and 18 independently selectable suction cups, electronically controlled sheet centering system and drives with brushless motors. It can load single or multiple sheets of any material used in the production of insoles and soles and is compatible with roll feeding.

Technical data

| Descriptions | Data |

|---|---|

| Work area (mm) | 1500mm |

| Cutting speed | 40 m/min |

| Air supply | 300 L/min a 6 bar |

| Power supply | 3 phase 400V – 50/60 Hz 3 phase 220V- 50/60 Hz (optional) |

| Maximum power consumption | 16 KW |

Find the right fit for your business

English

English Vietnamese

Vietnamese