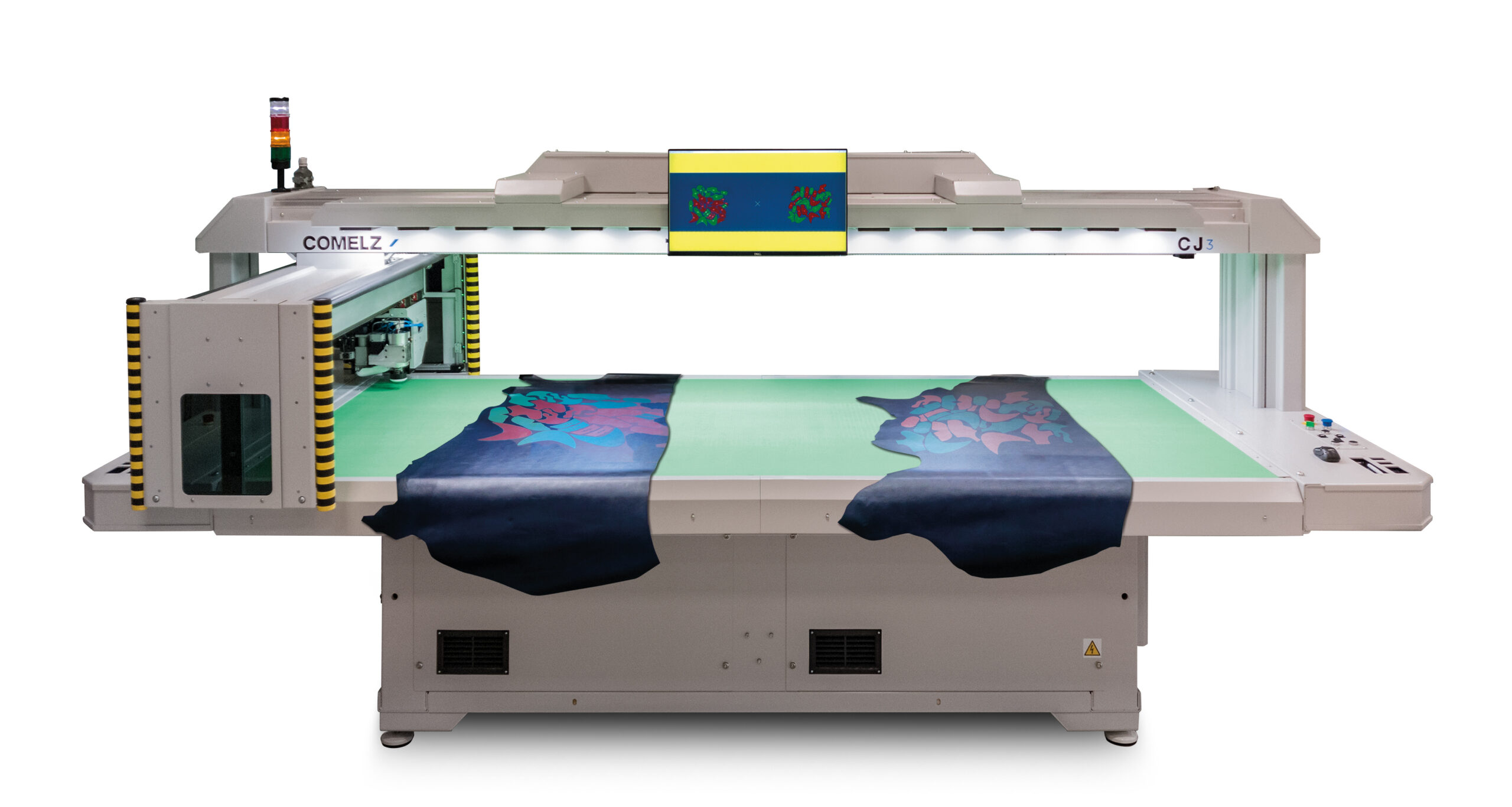

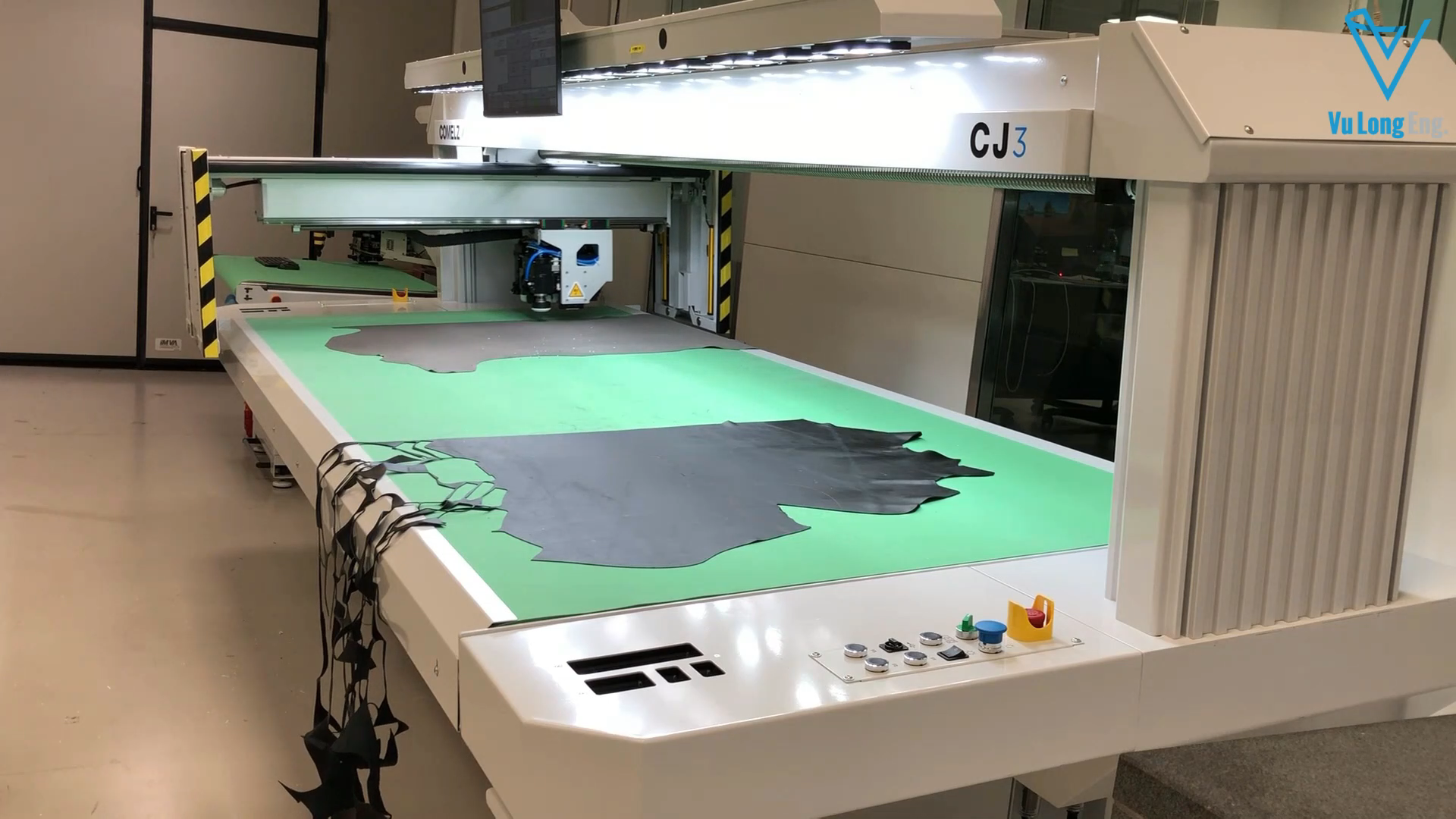

The most innovative fixed table cutting machine CJ Serie: CJ1 & CJ3

- SECTORS: Leather goods, Footwear, Automotive, Apparel and Furniture

- CONFIGURATIONS: multi-ply spread synthetic cutting, insole sheets, leather cutting

- Work area CJ1: 1600mm x 1000mm

- Work area CJ3: 3000mm x 1000mm

WHY CHOSE US ?

Comprehensive Leather Goods Manufacturing Solutions

Innovative Technology & Cutting-edge Software Systems

Industry Expertise with 13+ Years of Experiences and Dedication

Southeast Asia Trusted Partners

The CJ1 – CJ3 series is the expression of Comelz’s goal to create flexible, versatile though high performing, technologically advanced and truly innovative cutting machines..

SAFETY FEATURES

Fixed table machine where the operator must work next to the cutting devices can create safety relates issues. Comelz developed the first machine with triple protection from the cutting devices (two pairs of safety light curtains, a shifting cover and two pivoting plates on the front and the back of the arm.

PROJECTION

CJ machines can be equipped with regular LCD projectors or with laser projectors (optional). In both case the projectors are placed on the back of the suspended bridge and therefore the operator body does not interfere with the projection. The projection angle maximizes the light intensity of the projection.

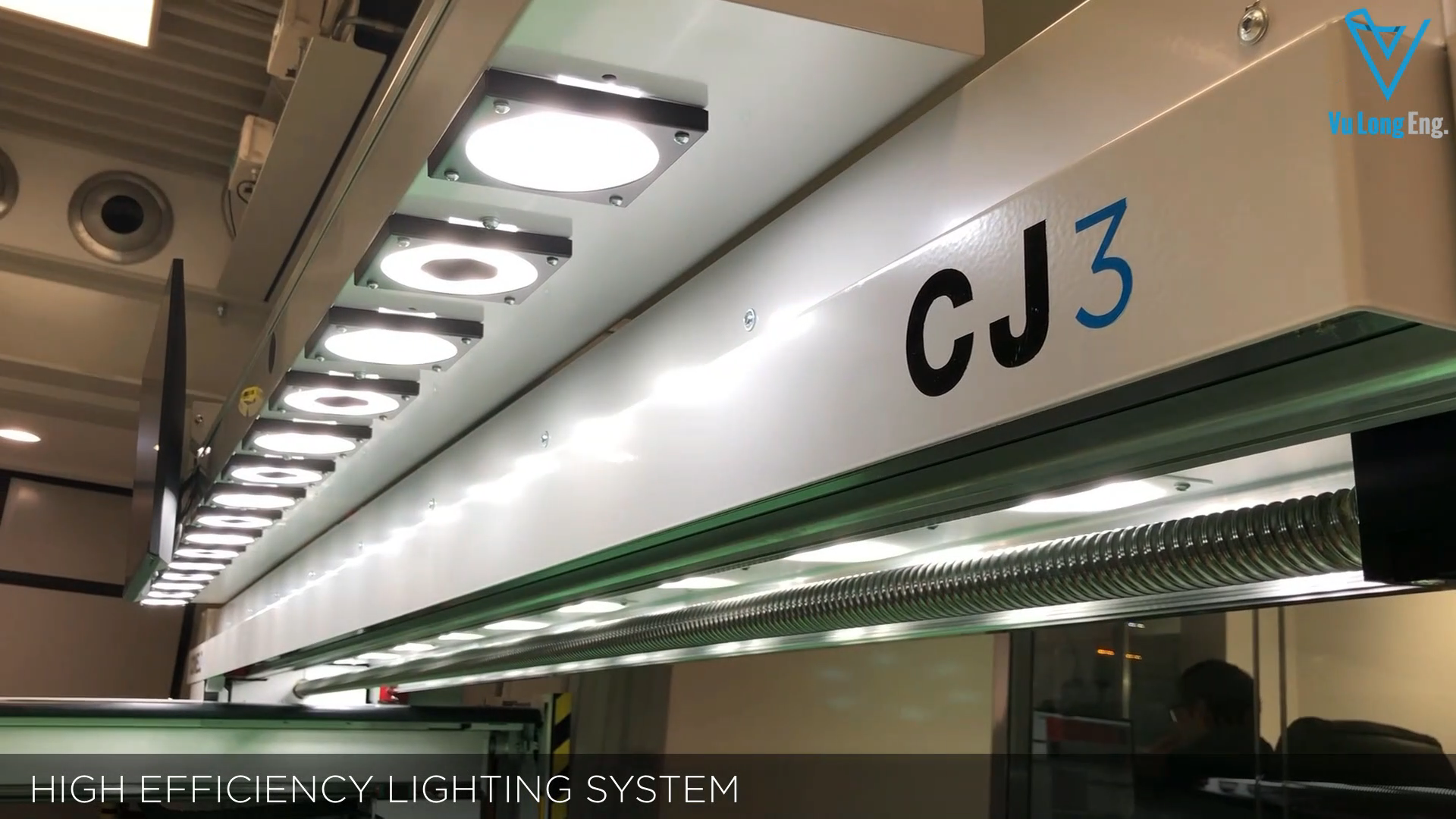

LIGHT (Optional)

The suspended bride is the perfect place to support the optional LED lightning system. The light intensity can be adjusted manually by the operator or automatically by the software based on the particular operation that is done in a particular area of the work table (part placing, cutting, part collection).

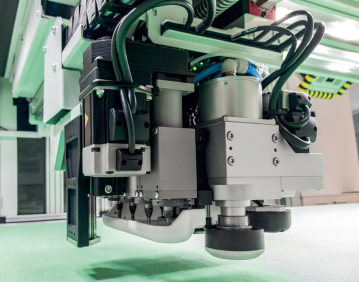

State-of-the-art multitools cutting head

The machine, even in the standard configuration, has most of the same state-of-the-art features available on Comelz top of the line machines:- 7 tool cutting head (high frequency pneumatic knife, 4 independent punching units, pen, pin punch).

high-end endless screws (in place of more economical drive belts or rack-and-pinion systems).

– micro-partialization system for the vacuum of the cutting area.

– vacuum pump (up to 17.5KW) enclosed in a cooled and sound-proofed area inside the machine

– electronic lubrification system for the cutting unit.

– isolation transformer for protection against most issues on the electric power supply.

– Comelz software for machine control and automatic nesting highly regarded for being user friendly, open, easily interconnected, and scalable.

VISION (Optional)

The suspended bride is the perfect place to support the optional Vision system. Thanks to the Comelz advanced multicamera Vision system, it is possible to perform a: vision-controlled cutting (textile with patterns/logos), final trimming operations and leather digitalization for online automatic nesting.

Technical data

| Descriptions | Data |

|---|---|

| Work area CJ1 (mm) | 1600mm x 1000mm |

| Work area CJ3 (mm) | 3000mm x 1000mm |

| Cutting speed | 60 m/min |

| Maximum punching frequency (for each head) | 600 p/min |

| Air supply | 150 L/min a 6 bar |

| Power supply | 3 phase 400V – 50/60 Hz 3 phase 220V- 50/60 Hz (optional) |

| Maximum power consumption | 20 KW |

Find the right fit for your business

Block "sp-1-faq-block" not found

Vietnamese

Vietnamese 中文 (中国)

中文 (中国)