Máy phun keo I388

Maximize Efficiency with the Intercom I388 spraying machine

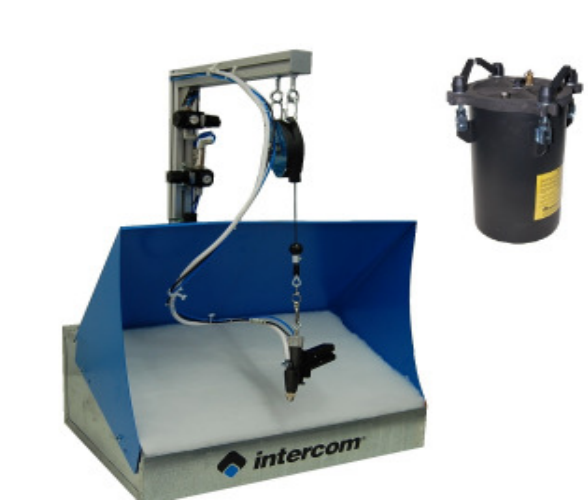

Intercom Srl proudly presents the Intercom I388 spraying machine—the ultimate solution for adhesive spraying in the leather and footwear industries. Designed to enhance productivity, ensure precision, and maintain a clean working environment, this advanced system guarantees superior adhesive application for every project.

Key Features:

-

High-Performance Vacuum Bench:

✔ Equipped with a powerful yet silent motor, the vacuum bench absorbs excess adhesive, keeping the workspace clean and safe. -

Versatile G6 Spray Gun:

✔ Designed for both wide-area and detailed adhesive spraying, with an adjustable spray width from 3 mm to 50 mm, ensuring flexibility for all types of applications. -

Non-Stick Stainless Steel Tank:

✔ Features a 10-liter stainless steel tank with Teflon coating, making it easy to clean and maintain, while ensuring durability over time. -

Mobile and Flexible Design:

✔ Equipped with wheels for easy movement, allowing for better workspace organization and efficiency. -

Adjustable Settings:

✔ The spray gun allows fine-tuning of adhesive quantity, spray width, and distribution quality, adapting seamlessly to various material thicknesses.

Why Choose the Intercom I388?

-

Boost Productivity:

✔ With fast and precise adhesive spraying, the I288 significantly reduces application time and enhances production efficiency. -

Superior Quality:

✔ Ensures even and consistent adhesive distribution, improving the durability and aesthetics of finished products. -

Cost-Effective:

✔ Reduces adhesive waste through precision spraying, lowering operating costs and requiring minimal maintenance. -

Eco-Friendly Solution:

✔ Uses Ecostick® water-based adhesives, minimizing environmental impact and promoting a safer, healthier workspace.

Upgrade Your Production with the Intercom I388

The Intercom I388 spraying machine is more than just a machine—it’s a strategic investment in quality, efficiency, and sustainability. Designed to meet the high standards of the leather and footwear industries, this innovative adhesive application system ensures optimal results, reduced costs, and increased production efficiency.

TẠI SAO CHỌN CHÚNG TÔI ?

Giải pháp toàn diện cho ngành giày và túi xách

Công nghệ tiên tiến và Hệ thống phần mềm hiện đại

15+ năm kinh nghiệm về máy tự động cho ngành giày da và túi xách

Đối tác tin cậy và toàn diện khu vực Đông Nam Á

Item description : I388

The machine is composed by:

– Vacuum bench created to be placed on the working plane and equipped with a silent and powerful engine to contain even more the nebulized adhesive.

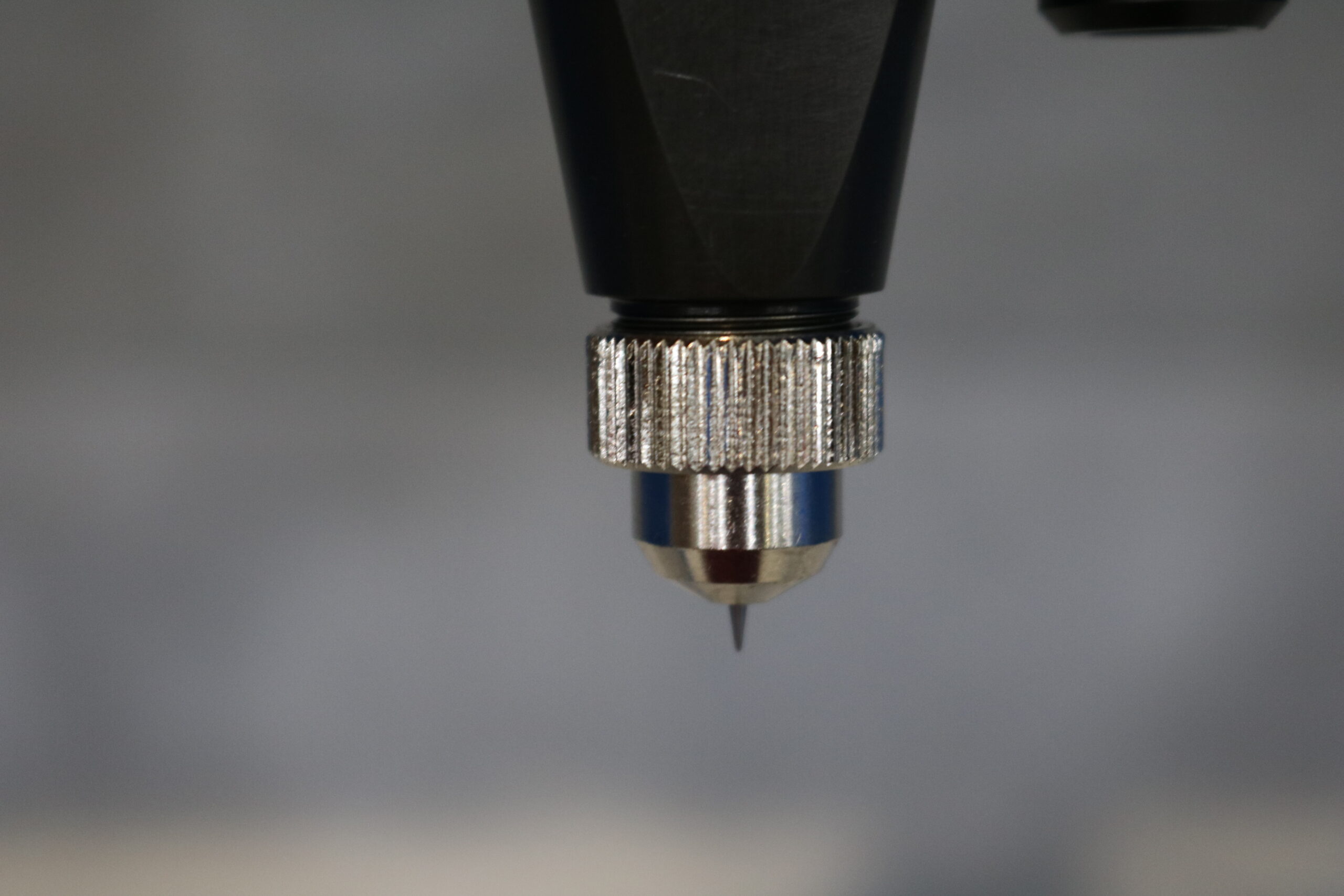

– Spray gun G6 designed for both precise and large areas bonding. In particular it is possible to spray the glue from a minimum of 3 mm up to a maximum of 50 mm.

– Stainless steel tank 10 lt. capacity treated with non-stick Teflon.

The operator, after starting the machine, can place the materials on the working plane so to make maximum use of the intake on the working plane for both keeping the materials standing and absorbing the nebulized adhesive.

All the spray gun functions can be adjusted: quantity of adhesive, width of jet and quality of distribution even on different thicknesses.

For a proper functioning of the vacuum bench it is recommended to replace the filter each time is visibly dirty or when the vacuum bench is not intaking properly.

A jet of air immediately before and after the adhesive nebulization keeps the nozzle constantly clean.

Our systems are maintenance free.

The tank is conceived in a way that allow the use of the adhesive in bag in box avoiding to make dirty the tank and to filter the glue thus preventing the contact with air which can alter its properties.

Specific:

| Capacity m3/h: 800 | Volt: 230 | Prevalence: 70 | Air lt/min: | Bar exercise: 0 |

| Decibel (dB): 63,3 | Watt: 102/135 | Hertz: 50/60 | Ampere: 0,45/0,60 | Average consumption: |

| Gross Weight kg: 34 | Tare Kg: 3 | Lenght mt: 0,46 | Height mt: 0,82 | Volume m3: 0,28 |

| Net Weight kg: 31 | Width mt: 0,60 | Usable Depth: 60 x 37 | ||

English

English 中文 (中国)

中文 (中国)